Cancel

CE71988SC

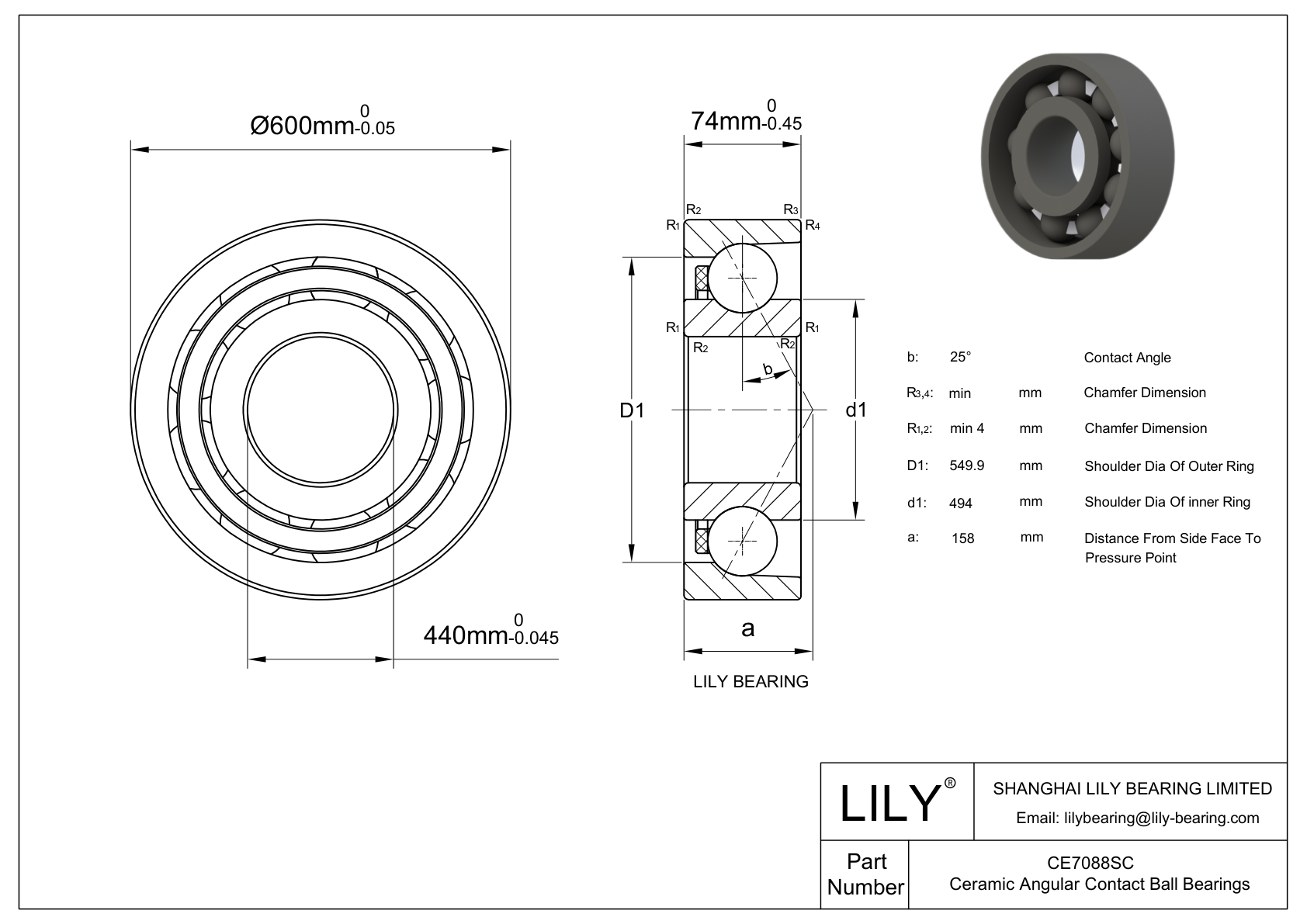

| Part Number | CE71988SC |

| System of Measurement | Metric |

| Part No | 7988 ACMB |

| Bearing Type | Ball |

| Contact Angle | 25° |

| For Load Direction | Angular Contact |

| Construction | Single Row |

| Seal Type | Open |

| Bore Dia | 440 mm |

| Bore Dia Tolerance | -0.045 mm to 0 |

| Outer Dia | 600 mm |

| Outer Dia Tolerance | -0.05 mm to 0 |

| Width | 74 mm |

| Width Tolerance | -0.45 mm to 0 |

| Shoulder Diameter Inner Ring (Large Side Face)(d1) | 494 mm |

| Shoulder Diameter Outer Ring (Large Side Face)(D1) | 549.9 mm |

| Chamfer Dimension (r1 2)(min) | 4 mm |

| Distance Pressure Point (a) | 158 mm |

| Ring Material | Silicon Carbide |

| Balls Material | Sic |

| Cage Material | PEEK |

| Dynamic Radial Load | 20516 lbf |

| Static Radial Load | 42084 lbf |

| Max Speed (X1000 rpm) | 0.77 |

| Lubrication | Dry |

| Temperature Range | -176 to 2192 °F |

| ABEC Rating | ABEC-1 |

| ROHS | Compliant |

| REACH | Compliant |

| Weight | 24.4 kg |

Design Features of CE71988SC Bearing

CE71988SC bearing integrates the remarkable properties of silicon carbide (SiC) with a single-row angular contact configuration, offering a blend of durability and performance. Its bore dia is 440 mm. Its out dia is 600 mm. Its width is 74 mm. CE71988SC bearing is a specialized category of bearing crafted for high-endurance and precision-demanding applications.

What Benefits Can CE71988SC Bearing Provide?

- High-Speed Performance: Ideal for applications requiring high-speed rotation due to silicon carbide’s low friction properties.

- Exceptional Durability: Silicon carbide’s extreme hardness enhances wear resistance, extending the bearing's lifespan.

- Thermal Stability: It performs reliably in high-temperature environments, maintaining integrity and function.

- Corrosion Resistance: Highly resistant to corrosion, suitable for use in harsh chemical environments.

- Electrical Insulation: The non-conductive nature of silicon carbide prevents electrical erosion, beneficial in electrically sensitive applications.

- Precision Operation: The single-row design ensures accurate control, making this bearing ideal for precision machinery.

What Can CE71988SC Bearing Be Used for?

CE71988SC Bearing is ideal for applications such as:

- High-Speed Machinery: Perfect for high-speed spindles and precision tools requiring rapid and accurate motion.

- High-Temperature Applications: Suited for equipment in high-temperature settings, like metallurgical and chemical processing.

- Corrosive Environments: Useful in chemical processing for their strong corrosion resistance.

- Electrical and Electronic Equipment: Ideal for applications needing non-conductive properties to prevent electrical erosion.

- Advanced Engineering: Appropriate for aerospace and defense sectors, where precision and durability are critical.

Recommended Products