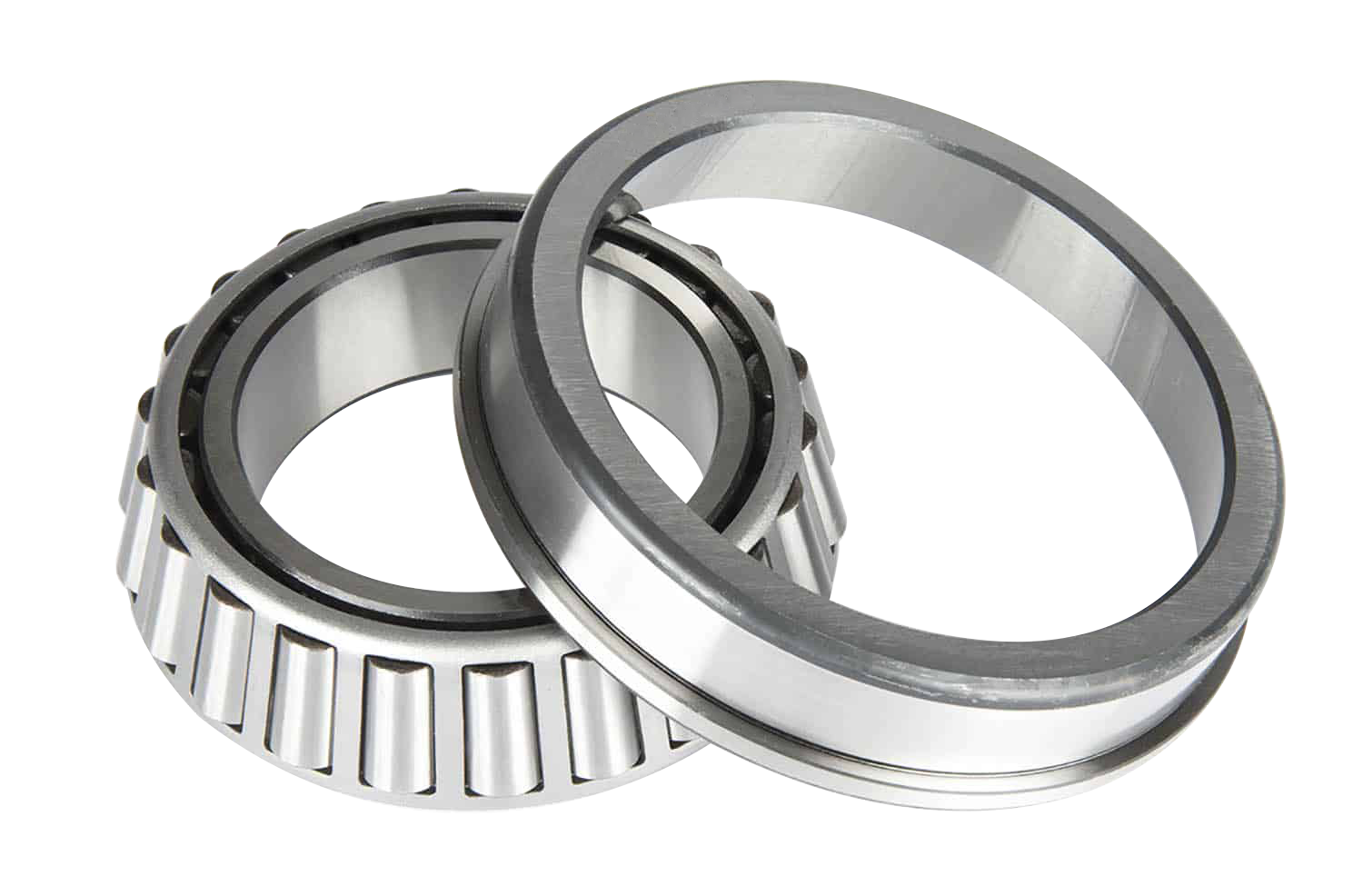

TSF (Single Row Tapered Roller Bearings with Flange) (Metric) are designed to accommodate combined loads, i.e. radial and axial loads acting simultaneously. The extensions of the raceways intersect at the same point on the bearing axis to realize real rolling. Thus, TSF (Single Row Tapered Roller Bearings with Flange) (Metric) have low frictional torque during operation. The axial load capacity of TSF (Single Row Tapered Roller Bearings with Flange) (Metric) increases as the contact angle α increases. The size of the contact angle (usually 10° to 30°) is related to the calculated coefficient e. The larger the value of e, the larger the contact angle.

Material: chrome steel, stainless steel

Chrome steel is the most common material used for TSF (Single Row Tapered Roller Bearings with Flange) (Metric) because of its characteristics of high load capacity and low noise. When clients needs the rust prevention,

the 440c stainless steel is recommended. Such stainless steel can withstand high load and high speed at the same time and the material also has the function of rust prevention.

Precision: ABEC-1 to ABEC-5

Factors to be considered when choosing an ABEC grade include radial and axial runout requirements, bore and OD fits, and the audible noise level. Lily Bearing offer these types of grades which show the available selection of bore and OD size tolerances, and the radial runout limits for each. ABEC of Grades 3 is the first choice for routine applications. Typically, race finish and race geometry are superior in ABEC 5. These grades are generally recommended generally for precision assemblies where low noise, minimal runout, and long life are important considerations for TSF (Single Row Tapered Roller Bearings with Flange) (Metric).

Sizing: Bore Dia from 7.937 mm to 1270.000 mm

Sealing types

There are several sealing types of TSF (Single Row Tapered Roller Bearings with Flange) (Metric). They are open type TSF (Single Row Tapered Roller Bearings with Flange) (Metric), sealed type (rubber seal) TSF (Single Row Tapered Roller Bearings with Flange) (Metric) as well as shielded type (metal shield) TSF (Single Row Tapered Roller Bearings with Flange) (Metric). Open type TSF (Single Row Tapered Roller Bearings with Flange) (Metric) are the most common, while other seal categories require customization.

Features and advantages of TSF (Single Row Tapered Roller Bearings with Flange) (Metric)

Low Friction

The optimized roller designs on the retaining edges and the surface finish of the retaining edges can promote the formation of a lubricant film, thus reducing friction. This can reduce the heat generated by friction and the wear of the flange. In addition, TSF (Single Row Tapered Roller Bearings with Flange) (Metric) can better maintain preload and reduce noise levels during operation.

Long service life

Convexity raceways, in detail, the shape of logarithmic raceways of TSF (Single Row Tapered Roller Bearings with Flange) (Metric) can optimizes load distribution along the contact surface, reduces stress peaks at the roller ends, and reduces sensitivity to misalignment and shaft deflection.

Improved operational reliability

The optimized surface treatment of the contact surface between the roller and the raceway can facilitate the formation of the fluid dynamic pressure lubricant film.

Consistency of roller profiles and dimensions

The rollers, which are integrated in TSF (Single Row Tapered Roller Bearings with Flange) (Metric), are manufactured to extremely precise tolerances and dimensional accuracy, so much so that they are almost identical. This provides optimum load distribution in TSF (Single Row Tapered Roller Bearings with Flange) (Metric), reduces the noise and vibration levels, and enables more precise preload.

Rigid bearing applications

In a certain application, a single row tapered roller bearing is often required to be adjusted in conjunction with another tapered roller bearing. Rigid bearing applications can be achieved by applying a preload.

Running-in period with peak temperature drop

TSF (Single Row Tapered Roller Bearings with Flange) (Metric) usually have a running-in period. During this period, the TSF (Single Row Tapered Roller Bearings with Flange) (Metric) for the conventional design mode experience a lot of friction which might result in wear. This will cause the bearing temperature to rise.

Provided that the bearings are correctly mounted and effectively lubricated, Lily Bearing can offer you the best solution. The solution can significantly reduce the friction, the wear during operation and the large amount of heat generated during friction.

Separability and interchangeability

TSF (Single Row Tapered Roller Bearings with Flange) (Metric) are separable in design. The inner ring (tapered inner ring) with the roller and cage assembly can be mounted separately from the outer ring (tapered outer ring). In addition, tapered roller bearing components of the same size can be fully interchangeable. These characters can help mounting, dismounting as well as maintenance inspection operate smoothly.

System of Measurement: Metric

Lubrication: Factory Lubrication From a Stock of Several Hundred Lubricants

As the lubrication expert trusted by grease manufacturers, we know how important it is to find the right grease for your bearing application. With over 20 years of experience and knowledge, we are confident that we can match the best lubrication solution for our clients. What’s more, we can also use client-specified oil or grease lubricants.

Temperatures

Normal chrome steel TSF (Single Row Tapered Roller Bearings with Flange) (Metric) can be used at constant temperatures of 120°C or intermittent temperatures of up to 150°C. Above these temperatures, the load capacity of the chrome steel will reduce. By means of special heat treatment processes and the addition of high temperature grease, we can also customize TSF (Single Row Tapered Roller Bearings with Flange) (Metric) for high temperature resistance.

Typical applications

TSF (Single Row Tapered Roller Bearings with Flange) (Metric) are often used for moderate speed, heavy duty applications. In such applications, durability is required. Typical applications of TSF (Single Row Tapered Roller Bearings with Flange) (Metric) are as follows:

Gearing systems and transmissions

Gearing systems and transmissions  Thermal power coal transporters

Thermal power coal transporters

Port Equipment

Port Equipment  Rubber and other industrial applications

Rubber and other industrial applications

Machine tool spindles

Machine tool spindles  Gear Reducer

Gear Reducer

Automotive Drive Axle

Automotive Drive Axle  Aircraft wheels

Aircraft wheels

Agricultural wheels

Agricultural wheels  Tensioning roller

Tensioning roller

Raking machine

Raking machine  Construction and mining equipment

Construction and mining equipment

railroad axle-box

railroad axle-box

Advantages & Buying and Using experience

Have been specializing in TSF (Single Row Tapered Roller Bearings with Flange) (Metric) for 22 years,our company is able to effectively deal with all kinds of difficulties encountered by our clients in bearing applications. In addition, our company has thousands of bearings in stock and can provide bearings which are rare in the market. We have rich experience in international trade, and most of our products can be shipped on the same day as the order is received. It is worth mentioning that we have much experience in serving US companies. According to statistics, 60% of our clients are from North America. For instance, Tesla, Google, NASA and other international famous companies are our loyal clients. They purchased our bearings and spoke highly of them. Furthermore, our bearings are widely used in some world-class products. A case in point, our bearings have been used in the center console of Mercedes-Benz with s-series.

Our company is not only a bearing seller, but also an expert in bearing solutions. We have a strong team of skilled engineers and a large service team, the mission of which is 'client-oriented'. Our experts have rich experience in serving end-users and well-established industry solutions, and can provide customized bearing solutions according to your actual working conditions.

Close

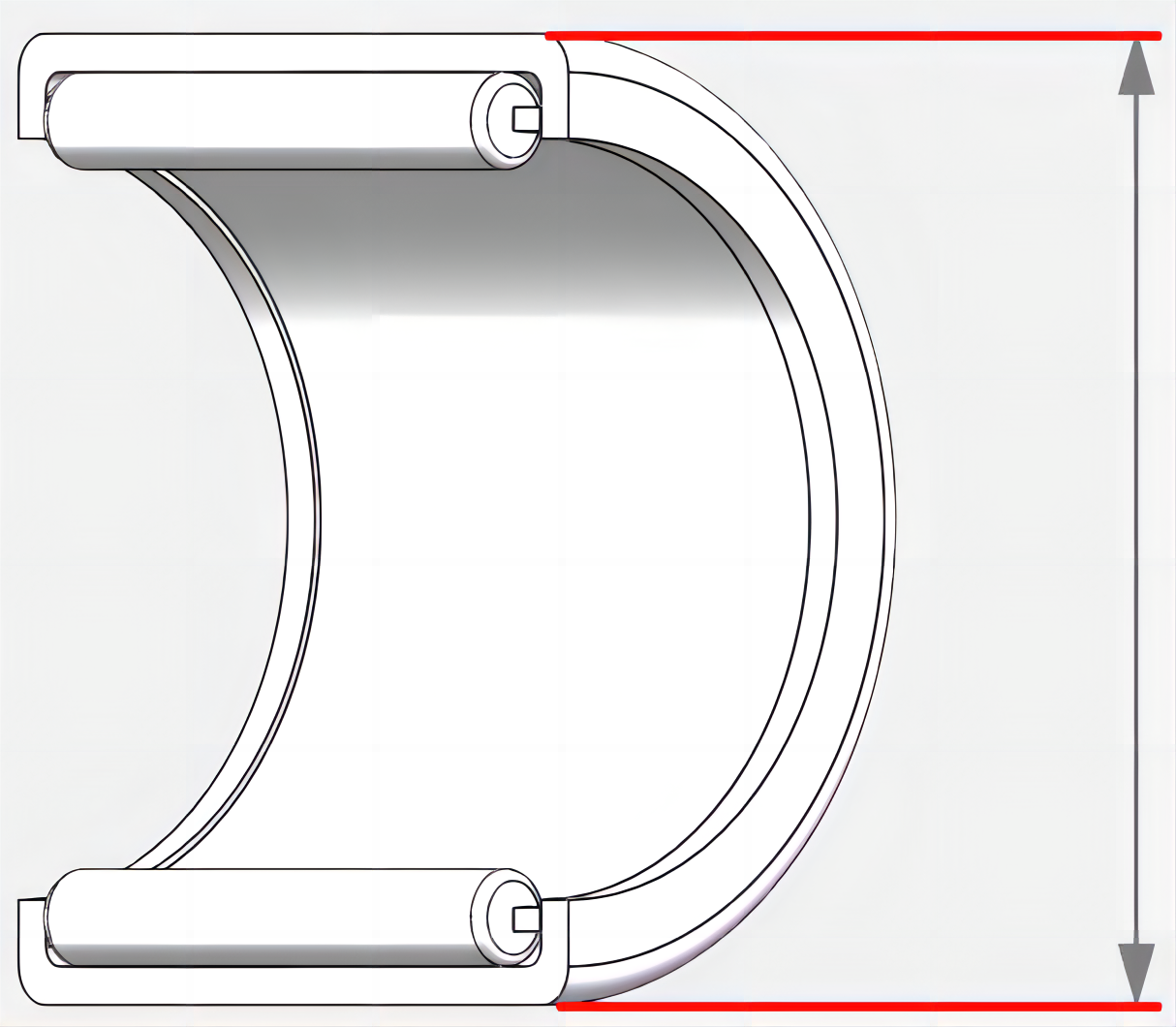

TSF (Single Row Tapered Roller Bearings with Flange) (Metric)

Flanged cups to facilitate axial location

TSF (Single Row Tapered Roller Bearings with Flange) (Metric)

Flanged cups to facilitate axial location

Gearing systems and transmissions

Gearing systems and transmissions

Port Equipment

Port Equipment

Machine tool spindles

Machine tool spindles

Automotive Drive Axle

Automotive Drive Axle

Agricultural wheels

Agricultural wheels

R

R

railroad axle-box

railroad axle-box