Cancel

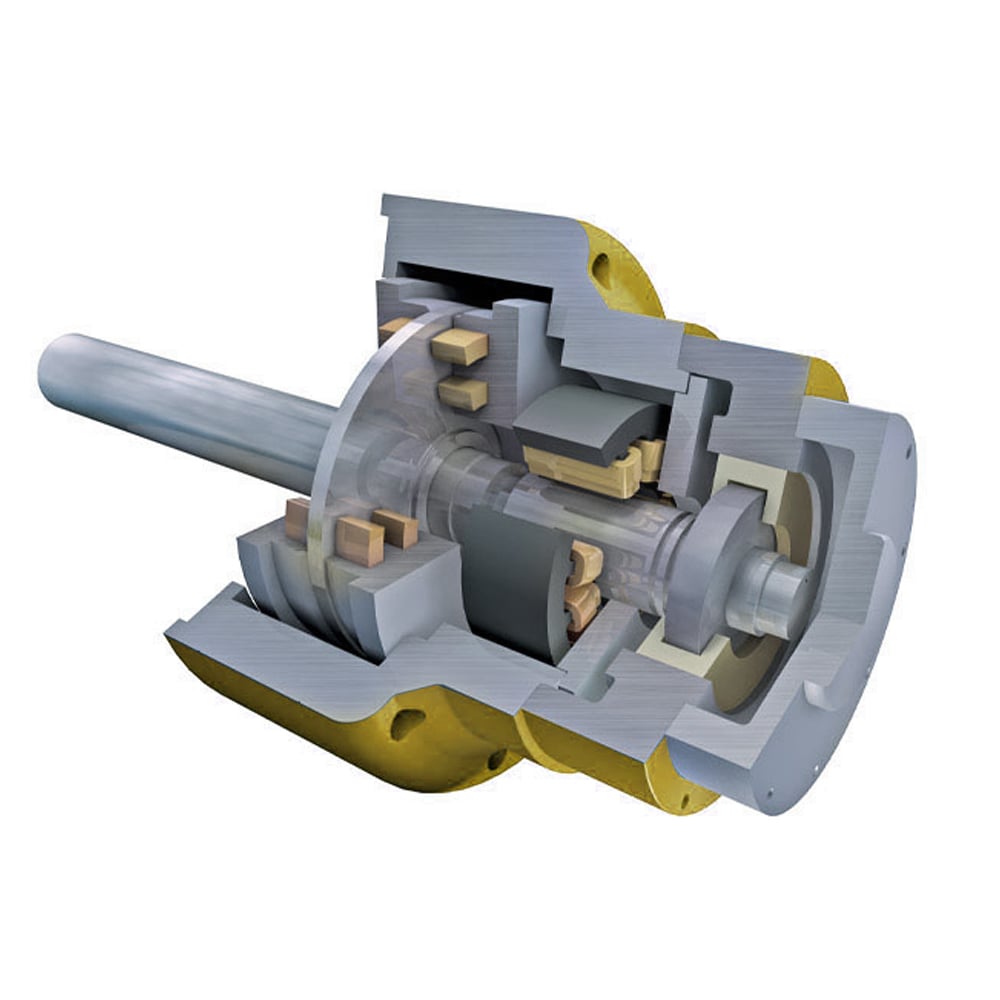

Silicon Nitride Ceramic Bearings in The High Temperature Reactor Practicing Strong Body

In the high temperature and high heat, strong magnetic vacuum, strong corrosion and strong pressure of the harsh conditions of the environment, we can often see the?figure?of ceramic bearing. They appear to solve the majority of engineering and users of the urgent needs.

Our production of ceramic bearings with non-magnetic, non-polluting, high temperature, corrosion resistance, self-lubricating and so on. The main materials are: alumina, zirconia, silicon nitride, silicon carbide, tungsten carbide and so on.

Ceramic bearings application examples are numerous, we first look at the silicon nitride ceramic bearings in the application of high temperature reactor.

Three months ago a customer needs us to provide a can be applied to the high temperature reactor ceramic bearings, the customer said the high temperature reactor bearings need high temperature 800 degrees to 1000 degrees, the speed of 10000 rpm, size: 35 * 62 * 14mm.

From the above can be determined that the bearing type es 6007 silicon nitride ceramic bearings, so we recommend to customers recommend the use of silicon nitride ceramic bearings. At the beginning of the customer that the whole ceramic bearing means: bearing the inner and outer rings and the ball, as well as the cage and dust cover are ceramic. Of course, after all, the customer is not a professional manufacturer of bearings, after I give him the explanation. They understand that most of the ceramic bearings are inside and outside the circle and the ball is ceramic, dust cover and cage is engineering plastics. Such as: PTFE, PEEK, POM, PA66 and other materials.

From this example, we recommend that customers use silicon nitride full of ceramic bearings, the full ball bearing mean that the cage is not installed in the bearing, in bearing only ball inside. Customers do not understand the other bearings are not all have a cage? So the use of full-scale silicon nitride bearings is not affecting the bearing speed?

I told customers that the full structure of the silicon nitride bearings, although slightly lower in the speed, but can achieve their required speed. Because this bearing needs high temperature of 800 degrees, so it can not use the cage, because the bearing industry is not currently resistant to such a high temperature of engineering plastics, if the use of plastic cage in this high temperature environment is sure to melt.

The current customer feedback our silicon nitride full ball bearing effect is good, so that silicon nitride full of ceramic bearings in the high temperature reactor practiced strong body.

CATEGORIES

- Miniature Bearings(2)

- Thin Section Bearings(1)

- Ceramic Bearings(7)

- Stainless Steel Bearings(3)

- Needle Roller Bearings(3)

- Spherical Roller Bearings(1)

- Thrust Ball Bearings(2)

- Roller Bearings(1)

- Tapered Roller Bearings(2)

- Slewing Ring Bearings(2)

- Angular Contact Ball Bearings(1)

- Sleeve Bearings(1)

- Others(44)

- Low Temperature Bearings(1)

- Ball Bearings(9)

- Bearing Load(4)

- Bearing Components(1)

- Types of Bearings(4)

- Thrust Bearings(1)

- Bearing Technical Knowledge(21)

- Aerospace Bearings(2)

- Polyurethane Rollers(2)

- Cam Follower(3)

- Linear Bearings(1)

- Spherical Bearings(1)

LATEST ARTICLES

-

Bearing Maintenance 101: A Guide to Extending the Life of Your Bearings

Bearing Maintenance 101: A Guide to Extending the Life of Your Bearings -

The Impact of Counterfeit Bearings On the Industry and How to Avoid Them

The Impact of Counterfeit Bearings On the Industry and How to Avoid Them -

Chrome Steel vs. Stainless Steel Bearings: Which Do You Need?

Chrome Steel vs. Stainless Steel Bearings: Which Do You Need? -

Magnetic Bearings: What They Are & How They Work

Magnetic Bearings: What They Are & How They Work -

Expert Tips On Installing & Removing Bearings for Industry Professionals

Expert Tips On Installing & Removing Bearings for Industry Professionals -

How Much Grease to Put in Bearings: A Comprehensive Guide

How Much Grease to Put in Bearings: A Comprehensive Guide