Bearing Maintenance 101: A Guide to Extending the Life of Your Bearings

Bearings are crucial in many industries, helping machines and devices run smoothly and efficiently. The lifespan and performance of bearings rely heavily on proper bearing maintenance. Good maintenance not only prolongs their life but also keeps them working at their best, which is essential in critical settings. This guide explores bearing maintenance thoroughly, with universal tips and tailored advice for different industries.

General Bearing Maintenance Tips

To maintain the performance and extend the lives of common bearings, follow these crucial steps for effective bearing maintenance.

- Regular Inspection: Conduct routine inspections to identify signs of wear, corrosion, or damage. Check for changes in noise and vibration levels, which can indicate issues before they lead to failure.

- Correct Lubrication: Choose the right lubricant for the bearing and its environment. Apply just enough bearing lubricant at regular intervals to reduce friction and prevent wear. Too much lubricant can gather dirt, while too little can cause the bearing failure early.

- Maintain Cleanliness: For effective bearing maintenance, keep the bearing environment clean to prevent contaminants from entering. Always clean bearings before inspections and use proper sealing techniques to shield them from dirt and debris.

- Proper Handling and Storage: Handle bearings with care to prevent physical damage. Store bearings horizontally in a clean, dry area in their original packaging to protect them from moisture and contaminants until they are ready to be installed.

- Proper Installation and Alignment: To extend the life of bearings, it's crucial to install and align them correctly using the right tools and techniques. Misaligned or improperly mounted bearings can lead to stress and uneven wear. Always ensure that bearings are not subjected to excessive force during installation to avoid damage.

- Check Temperature and Noise: Keep an eye on the bearing's temperature and listen for unusual noises. High heat or odd sounds may suggest problems like wear or insufficient lubrication that require quick action.

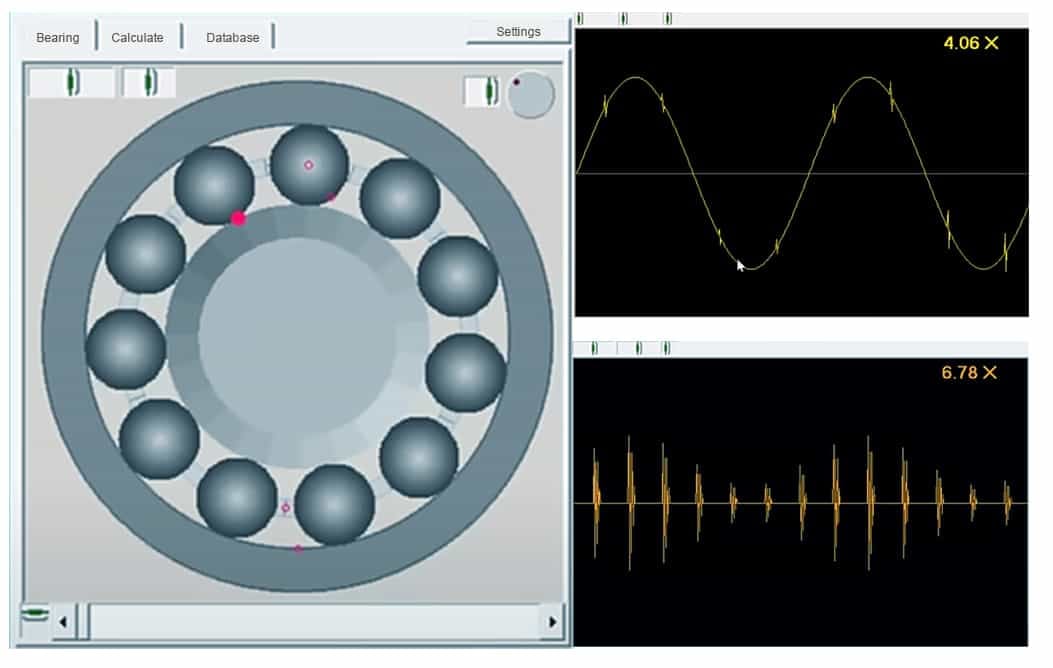

- Use Condition Monitoring Tools: Use tools to monitor bearing conditions, like vibration analysis, thermography, and acoustic emissions. These can help spot early signs of bearing failure.

Using Tools to Detect Bearing Conditions (Image Source: Mobius Institute)

By following these bearing maintenance tips diligently, you can ensure the long-term performance and durability of your bearings across various applications.

Industry-Specific Bearing Maintenance Practices

Each industry has its own unique needs and challenges for bearing maintenance. Knowing these requirements helps ensure that bearings operate effectively under specific conditions.

Bearing Maintenance in Medical Industry

In the medical field, bearings are critical components in a wide array of devices, from surgical tools to imaging equipment. Bearing maintenance is pivotal not only for device functionality but also for patient safety and compliance with stringent health standards:

- Sterilization Compatibility: Use bearings and lubricants that can handle frequent sterilizations. Choose 440C stainless steel bearings or ceramic bearings for their abilities to withstand high temperatures and prevent rust.

- Non-Toxic Lubrication: Use safe, medical-grade lubricants. They stay stable and harmless during sterilization and when touching human tissues.

- Precision Cleaning: Regularly clean bearings in medical devices to remove biological contaminants and residues from sterilization agents. Employ cleaning agents that are effective yet gentle enough to not damage the bearing materials.

- Corrosion Monitoring: Check bearings often for signs of corrosion or wear. Exposure to harsh sterilants and cleaners can speed up damage. Replace bearings at the first sign of wear to avoid failures in critical medical procedures.

- Vibration Analysis: Regularly check vibrations in high-precision medical equipment like MRI machines to make sure the bearings run smoothly. This helps catch any early wear or misalignment, keeping the equipment accurate and functional.

Following these bearing maintenance tips can help keep medical bearings dependable and efficient. This is vital for the performance of medical devices and the safety of patients.

Bearing Maintenance in Food and Beverage Industry

Bearings in the food and beverage industry need to handle tough conditions like regular washdowns and corrosive substances.

Here's how to do bearing maintenance effectively and meet industry standards:

- Materials Selection: Opt for stainless steel or food-grade composite bearings that resist corrosion and contamination.

- Food-Safe Lubricants: Use food-safe lubricants to keep things running smoothly and avoid contamination.

- Sealed Units: Use bearings with high-quality seals to keep water and dirt out during cleaning.

- Regular Inspections: Check for signs of wear, rust, or old lubricant to keep your equipment safe and working well.

- Maintenance Training: Train maintenance staff on the right ways to handle and clean food and beverage equipment to prevent damage to bearings during everyday use.

By focusing on these bearing maintenance practices, bearings in the food and beverage industry can achieve longer life spans and contribute to safer, more efficient production processes.

Bearing Maintenance in Robotics Industry

In robotics, precision and reliability are crucial. A thorough bearing maintenance is vital for smooth robotic movements. Here are some essential tips for robotics bearing upkeep:

- Precision Lubrication: Use special lubricants made for high-speed and precision tasks, ensuring they stay strong in the usual temperatures of robotics.

- Regular Calibration: Check bearings often to make sure they're working within their specific tolerances. It is essential for keeping robotic movements accurate.

- Clean Operating Environments: Keep the area clean to prevent dirt from getting into the bearings, which is crucial for precise tasks.

- Vibration Monitoring: Use tools that analyze vibrations to catch early signs of wear or failure in bearings, so you can fix issues before they cause big problems.

- Replacement Protocols: Set up schedules for replacing parts based on how much they're used, not just on time, taking into account the different demands on different parts of the robot.

Following these bearing maintenance practices can help keep robots working well and can ensure they perform reliably and accurately. This is important for automated tasks.

Bearing Maintenance in Automotive Industry

As is known, how long car ball bearings last depends on their quality, the conditions they're subjected to, and how well they are maintained. In the automotive industry, bearings deal with changing temperatures and loads. Proper bearing maintenance is key to keeping cars safe and reliable. Here’s how to do it:

- Temperature Monitoring: Regularly use thermal cameras or sensors to check if bearings are getting too hot. This can help you spot problems with lubrication or too much friction.

- Load Analysis: Examine the load conditions that bearings endure. This helps choose bearings capable of handling the particular stresses found in automotive settings.

- Lubrication Management: Use high-quality lubricants that can handle the extreme temperatures of car use. Make sure to lubricate regularly to avoid wear and tear from friction.

- Regular Inspections: Conduct frequent inspections to check for signs of wear or damage, such as noise or vibrations. Early detection of issues can prevent costly repairs and downtime.

- Environmental Considerations: Make sure bearings are kept safe from dirt, water, and road salts to prevent corrosion and early failure.

By practicing good bearing maintenance, you can make automotive bearings last longer and work better. Thus, it will improve the car's overall performance and safety.

Bearing Maintenance in Skateboarding

In skateboarding, bearings play a crucial role in wheel performance, impacting both speed and smoothness of the ride. Proper bearing maintenance is key to extending the life of skateboard bearings and enhancing the skateboarding experience:

- Regular Cleaning: Skateboarding areas often have dirt, dust, and debris that can get into bearings and lower their performance. Clean the bearings often with a proper solvent and re-lubricate them to keep them working smoothly.

- Impact Checks: Skateboard bearings are subjected to high impacts from jumps and tricks. Regularly inspect bearings for any signs of damage or deformation. Replace bearings that show visible damage or feel gritty when spun.

- Lubrication: Use lubricants that are specifically designed for skateboard bearings to reduce friction and protect against wear. Avoid over-lubrication, which can attract more grime and debris.

- Avoid Moisture: Water can rust bearings and degrade their performance quickly. Dry bearings thoroughly if they come into contact with water and lubricate them immediately after drying.

- Rotation Practices: Rotate bearings periodically between different wheels to ensure even wear. This practice helps extend the life of the bearings by distributing the wear evenly across all bearings.

By keeping up with these bearing maintenance suggestions, skateboarders can keep their bearings working well, lower the chance of breakdowns, and have a safer, smoother ride.

Learn More About Your Bearings at LILY Bearing

At LILY Bearing, we provide a lot of resources to help you keep your bearings in top shape. You can find detailed product details, maintenance guides, and expert advice on our site. Our aim is to give you all the information you need to make smart decisions about bearing maintenance.

Conclusion

Effective bearing maintenance is key to success in many industries. By using both general and specific maintenance practices, you can greatly increase the lifespan of your bearings and keep them running smoothly. For more detailed information and expert advice, check out LILY Bearing’s comprehensive resource center.

Keep Learning