Electrically Insulated Bearings & INSOCOAT Bearings

425 ProductsElectrically Insulated Bearings are a specialized category of bearings designed to prevent the flow of electrical currents through the bearing, a critical feature for protecting both the bearing and associated machinery from electrical erosion. As a brand name used by SKF Bearings, INSOCOAT bearings refer specifically to SKF's proprietary version of electrically insulated bearings.

Construction and Design

Electrically insulated bearings incorporate insulating materials into their design, typically by applying a non-conductive layer to the rings of the bearing. This can be achieved through various methods, including ceramic coatings or layers of insulating polymers. The insulating layer is carefully integrated to ensure it does not compromise the bearing's mechanical performance.

Bearings with ceramic coatings have different structures, such as:

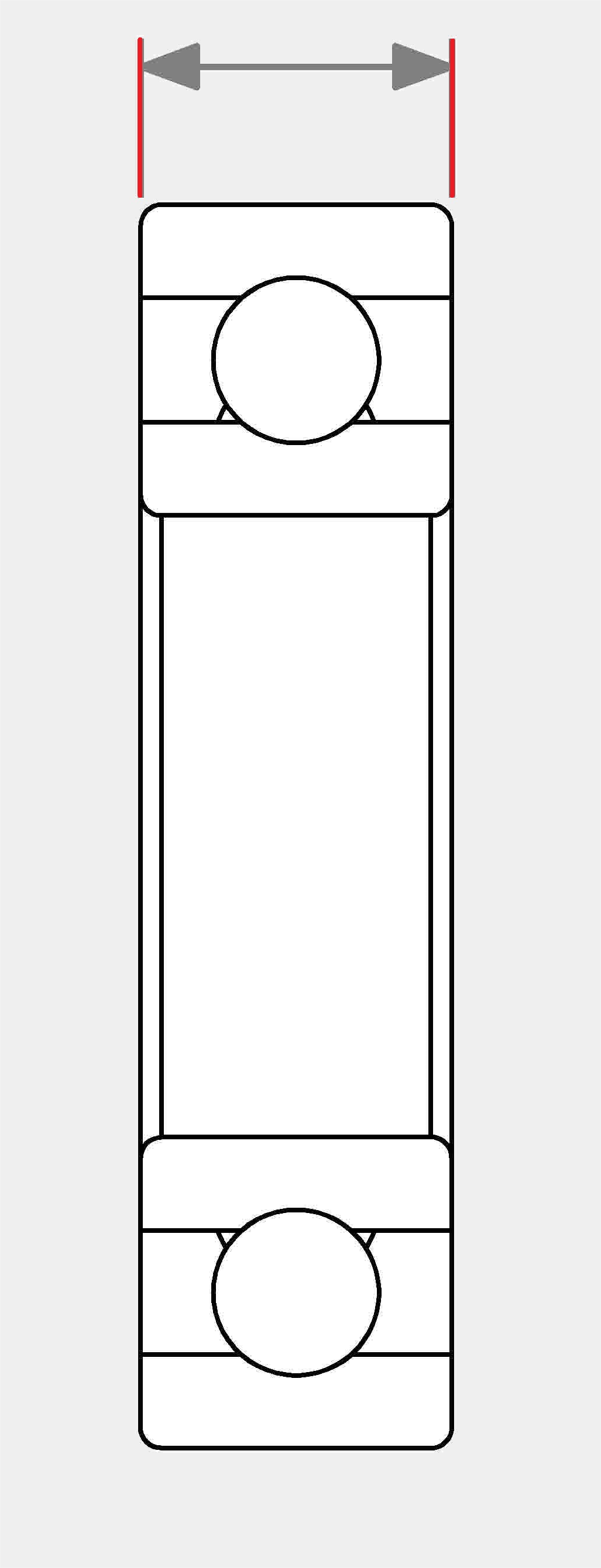

Ceramic Coated Deep Groove Ball Bearings:

- Dimension series: 6212-6226; 6312-6326

- Cages: brass

- Radial clearance groups: C3, C4

Ceramic Coated Cylindrical Roller Bearings:

- Design variants: NJ, NU, NUP

- Dimension series: 210-230, 310-330

- Cages: brass and polyamide

- Radial clearance groups: C0, C3, C4

INSOCOAT bearings are characterized by their aluminum oxide coating, applied through a sophisticated plasma-spray process that ensures a high-quality finish. The coating is applied to either the inner or outer ring, providing a durable barrier against electrical currents.

Features and Benefits

All Electrically Insulated Bearings have the following features:

- Electrical Insulation: Designed to prevent electrical currents from passing through, protecting against electrical erosion.

- High Voltage Resistance: Capable of withstanding high voltages, typically over 1000V, to protect internal components.

- Mechanical Integrity: Retain standard load-carrying and speed capabilities as non-insulated bearings.

- Reduced Maintenance: Lower frequency of maintenance and replacements due to protection against electrical damage.

For INSOCOAT Bearings, they also have other advantages:

- High Electrical Resistance: The aluminum oxide coating on these bearings ensures a minimum electrical resistance of 200 MΩ and can handle voltages up to 3,000 V DC.

- Consistent Electrical Performance: To counter the hygroscopic nature of plasma-spray coatings, INSOCOAT bearings are sealed with a unique treatment, safeguarding against moisture penetration.

Applications of Electrically Insulated Bearings & INSOCOAT Bearings

Electrically Insulated Bearings are widely used in applications where electrical currents can cause damage. These include electric motors and generators, variable frequency drives (VFDs), wind turbines as well as industrial pumps and compressors.

INSOCOAT Bearings, with their specific insulating properties, are particularly suited for:

- High-Frequency Applications: Effective in environments with high-frequency electric currents, such as those generated by PWM in frequency converters.

- High-Voltage Environments: Ideal for applications with high voltage requirements, offering enhanced protection up to 3,000 V DC.

- Railway and Traction Motors: In railway applications, where electrical insulation is crucial for safety and efficiency.

- Heavy Electrical Machinery: Suited for large-scale industrial electric machinery, where robust insulation is critical.