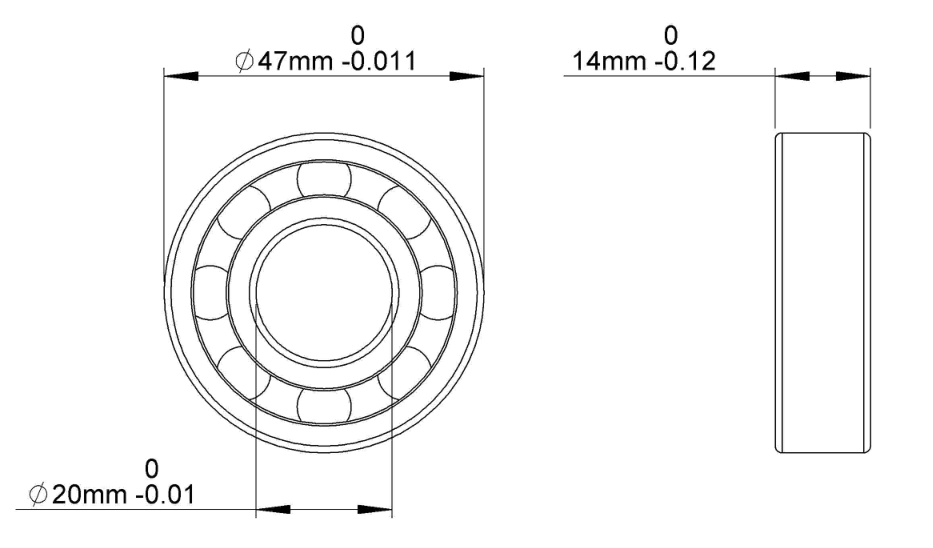

6204 Bearing: 20mm X 47mm X 14mm Deep Groove Design

The deep groove 6204 bearing is a staple in the machinery world, prized for its versatility and reliability. This blog post delves into the specifics of the 6204 bearing, providing engineers and technicians with the knowledge to select and use this component effectively.

Composition of 6204 Bearing

The 6204 bearing consists of an inner ring, outer ring, ball elements, and a cage, with a raceway groove slightly larger than the steel balls' radius. This design allows for point contact between the balls and the raceway, enabling the bearing to support both axial and radial loads. Typically, 6204 bearings are utilized in pairs to effectively manage internal axial forces and primarily bear radial loads under standard operating conditions.

6204 Bearing Dimensions

- Inner Diameter (ID): The 6204 bearing has an inner diameter of 20mm. This dimension is critical as it determines the fit on the shaft or spindle it is meant to accommodate.

- Outer Diameter (OD): The outer diameter is standardized at 47mm. This measurement is essential for the bearing to fit correctly within its housing or the machinery component it will operate in.

- Width (B): The width, or thickness, of the bearing is 14mm. This size contributes to the bearing's load capacity and overall stability within a system.

6204 Bearing Technical Specifications

|

Universal |

6204 |

|

Type |

Ball |

|

Inner/Outer Ring Material |

Steel |

|

Precision |

Grade 0 |

|

Inner Dimension d(Ø) |

20 |

|

Outer Dimension D(Ø) |

47 |

|

Width B (or T)(mm) |

14 |

|

Retainer Type |

Punching |

|

Load Direction |

Radial |

|

Specifications/Environment |

Standard |

|

Number of Raceway Ring Rows |

Single Track |

|

Size Standards |

Metric Series |

Features of 6204 Bearing

- Simple, versatile and robust design

- Made from GCr15 steel for durability and precision

- Suitable for high-speed rotation and moderate radial and axial loads

- Low friction, noise, and vibration

- Require little maintenance

6204 Bearing Seals

Selecting the appropriate seal for a 6204 deep groove ball bearing is not merely a matter of choice but a strategic decision that significantly affects the bearing's performance and longevity. Let’s explore the various seal options available for 6204 bearings, understanding their distinct advantages and suitable applications.

Open 6204 Bearings

Open 6204 Bearings are characterized by the absence of any shields or seals. This design ensures minimal frictional resistance, facilitating higher speeds and ease of maintenance. Without any barriers, these bearings offer optimal cooling, making them suitable for operations where temperatures can quickly escalate. However, they are best used in environments where contaminants are minimal, as the open design does not protect against debris or moisture ingress.

Single Shielded 6204 Bearings

Single Shielded 6204 Bearings (6204Z) come with a metal shield on one side of the bearing. This shield acts as a barrier against larger contaminants while still allowing for some exposure, which can be advantageous for certain lubrication or cooling requirements. The single shielded design is a compromise between protection and accessibility, providing a certain degree of contamination resistance while still maintaining the ability to service the bearing as needed.

Double Shielded 6204 Bearings

Double Shielded 6204 Bearings (6204ZZ) are an upgrade in protection with metal shields on both sides, offering better defense against a variety of contaminants, including dust and small particles. This configuration helps maintain the lubricant within the bearing, extending its service life. Double shielded bearings are a preferred choice in settings with higher levels of particulate matter, where the bearing needs to be safeguarded against the ingress of potentially damaging elements.

Rubber Sealed 6204 Bearings

Rubber Sealed 6204 Bearings (6204DDU, 6204LLU, 6204-2NSE, 6204H2RS) provide the highest level of sealing with rubber seals on both sides. These seals create a tight barrier against not just solid contaminants, but also liquids, making the bearing an ideal solution for applications exposed to moisture, corrosive substances, or a broad range of particulates. Rubber sealed bearings are optimal for harsh environments where the bearing requires the utmost protection to ensure functional integrity and longevity.

For more 6204 ball bearings and seal options — we have thousands of them. See some of them in the table below!

|

6204 ETN9 bearing |

6204-2RSH bearing |

6204-2RSL bearing |

|

6204-RSH bearing |

W 6204 bearing |

6204 N bearing |

|

6204 NR bearing |

6204-2RSH/VA947 bearing |

S6204 bearing |

|

6204 rs bearing |

6204-2rs bearing |

S6204 2RS bearing |

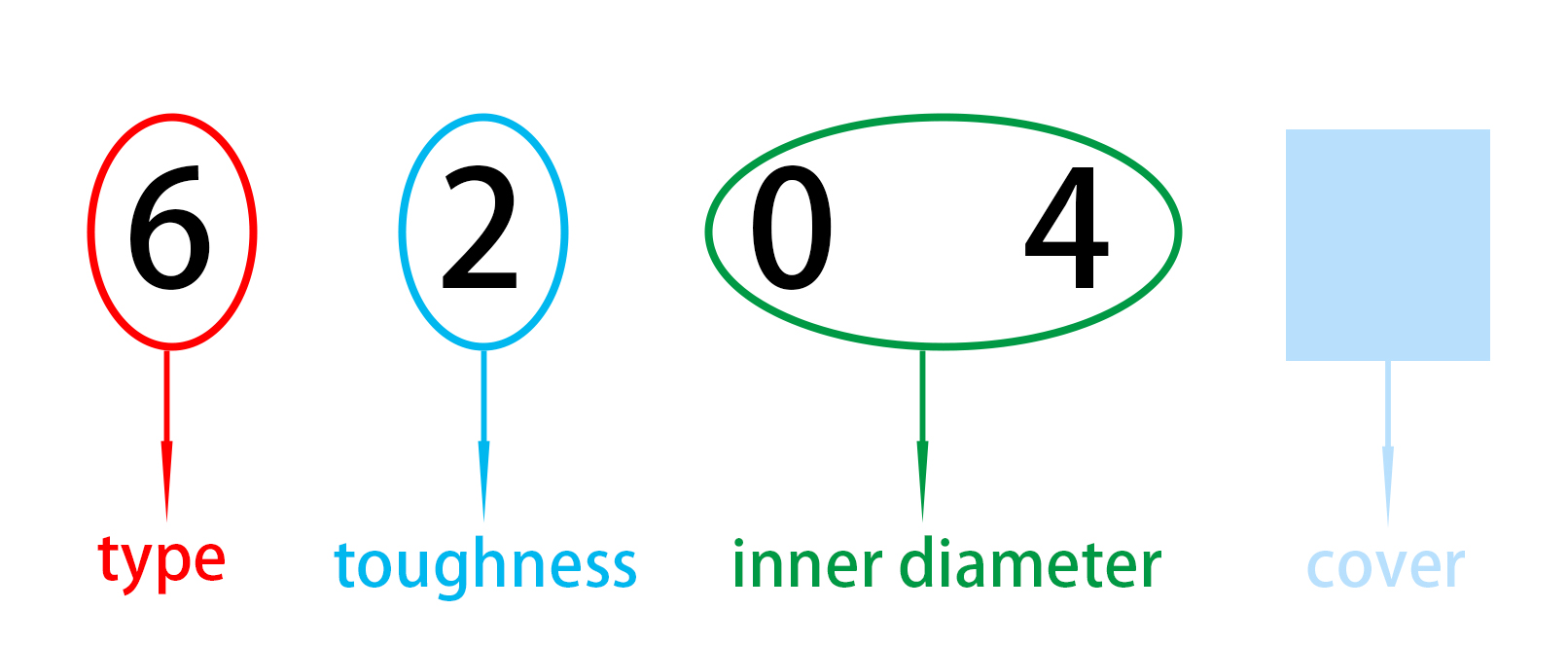

Code Meaning of 6204 Bearing

6 --- Single row deep groove ball bearing

2 ---Light

04 --- 20mm

About more about the code meaning, click “How to Read & Identify Bearing Number”.

Comparative Overview: 6204 Bearing Models Across Leading Brands

|

Bearing Seals |

NSK |

NTN |

MISUMI |

Nachi-Fujikoshi |

EZO |

|

Open Type |

6204 |

6204 |

B6204 |

6204 |

- |

|

Single Shielded |

6204Z |

6204Z |

B6204Z |

- |

- |

|

Double Shielded |

6204ZZ |

6204ZZ |

B6204ZZ |

- |

- |

|

Rubber Sealed |

6204DDU |

6204LLU |

B6204DDU |

6204-2NSE |

6204H2RS |

Selecting the Right 6204 Bearing: A Step-by-Step Guide

Navigating the Complexities of Bearing Selection

Each application demands a specific type of 6204 bearing, and understanding the coding and nomenclature is essential for making an informed choice. e.g.

- B6204: The basic open type, adaptable and easy to maintain.

- 6204Z: Equipped with a single metal shield for basic protection.

- 6204ZZ: Double metal shields for improved protection against contaminants.

- B6204DDU / 6204LLU / 6204-2NSE / 6204H2RS: Rubber seals on both sides for maximum durability in harsh conditions.

Applications

6204 bearings are essential in diverse applications, including automotive components, industrial machinery, household appliances, agricultural equipment, and electric motors. Their durability and versatility make them ideal for use in power tools, sports gear, office machines, and material handling systems.

Keep Learning