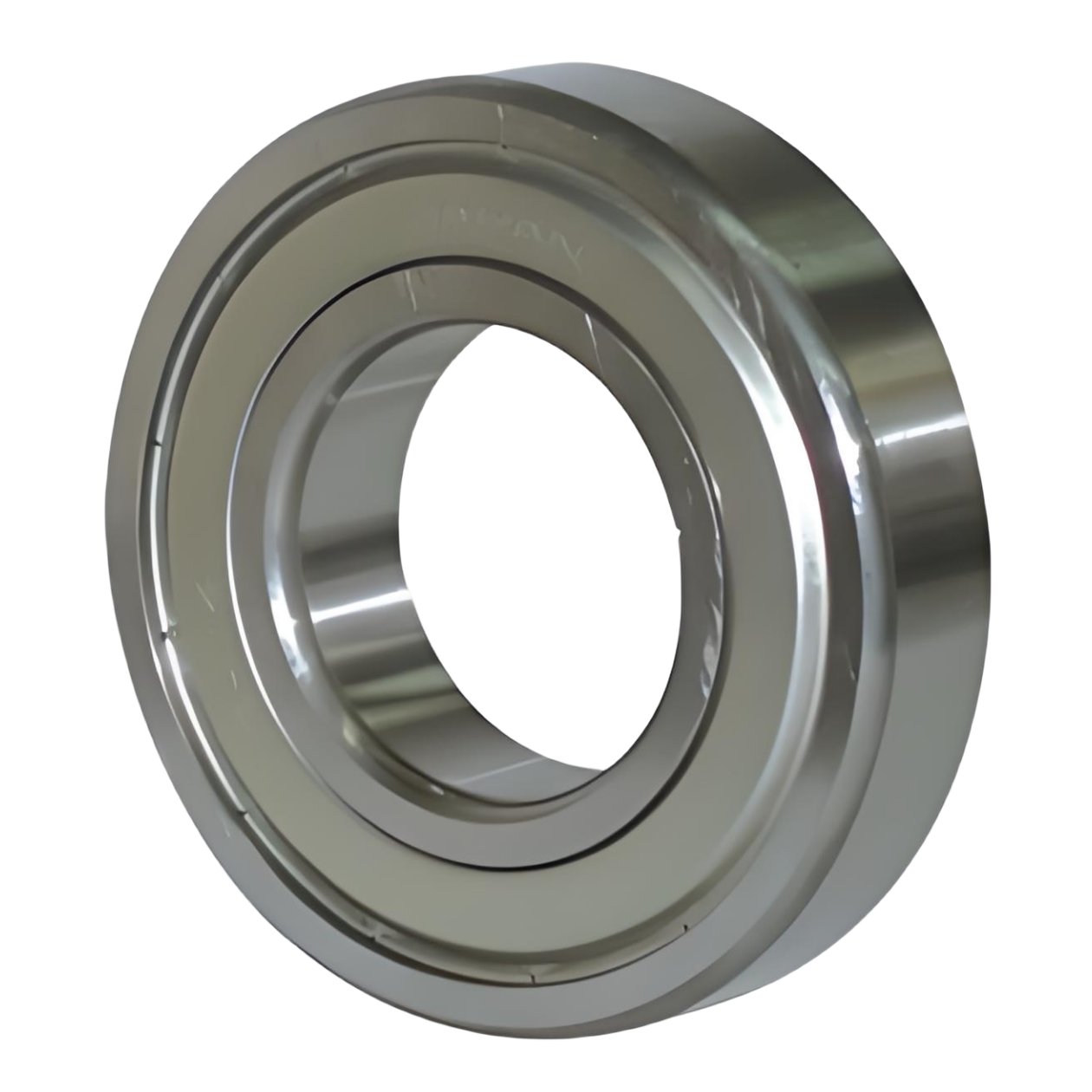

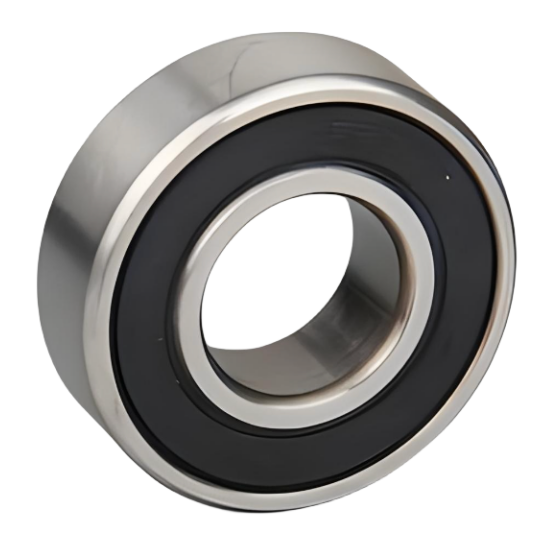

Stainless Steel Ball Bearings

3132 ProductsStainless Steel Ball

Stainless steel ball bearings are a crucial component in a wide range of equipment and machines. Known for their high performance and durability, stainless steel ball bearings are very common in a variety of industries.

Advantages of Stainless Steel Ball Bearings

- Corrosion Resistance: Ideal solution for applications in harsh environments, as other bearings are prone to rust or corrode in other forms.

- Durability: Can withstand heavy loads in challenging conditions

- Low Friction: Extended lifespan with their low friction design to minimize wear and tear

- Versatility: Offer High accuracy and versatility to be used in a wide variety of applications

Types of Stainless Steel Ball Bearings

- 440C Stainless Steel Ball Bearings: Known for high hardness and wear resistance, these bearings are ideal for heavy load applications and harsh conditions. They offer good corrosion resistance, though not as extensive as 316 or 304 grades, perfect for precision instruments and demanding industrial machinery.

- 316 Stainless Steel Ball Bearings: These bearings excel in corrosion resistance, especially against harsh chemicals and saltwater, making them ideal for marine, chemical processing, and food-grade applications. They are less hard than 440C bearings, suitable for moderate loads in more corrosive environments.

- 304 Stainless Steel Ball Bearings: Known for excellent corrosion resistance and popular choice of stainless steel bearings in the food and beverage industry

Applications of Stainless Steel Ball Bearings

- Food and Beverage Industry: Commonly used in equipment that is in high contact with food due to their high corrosion resistance and ability to withstand high temperatures

- Marine and Offshore Applications: Used in applications that are made to withstand harsh environmental conditions such as saltwater, humidity, and corrosive materials

- Chemical and Pharmaceutical Industry: Used in machinery that processes highly corrosive liquids and chemicals

- Medical Equipment: used to provide smooth and accurate imaging in applications such as CT scans and MRI machines

- Aerospace and Defense Industry: Used in high stress, high speed applications such as aircraft engines, weapon systems, and other critical components

Maintenance of Stainless Steel Ball Bearings

To ensure longevity and performance of stainless steel ball bearings, proper lubrication and maintenance is critical. Reduce wear and friction by lubricating the bearing with the appropriate lubricant for the application. Additionally, it is important to keep the bearings clean and to handle them carefully to prevent damage. A maintenance schedule should also be established to ensure that the bearings are inspected and maintained on a regular basis.

Conclusion

Stainless steel ball bearings excel in durability, corrosion resistance, and low friction, making them ideal for diverse industrial applications. Ensure their longevity with proper maintenance and lubrication. Discover our range of stainless steel ball bearings and stainless steel balls in various materials at LILY Bearing. For more information on materials, take a look at our materials page.