Bearing Failure Analysis

Our experienced bearing engineers can identify bearing failure problems and provide customers with cost-effective, actionable solutions.

Variables will always apply due to the different applications and environments, but the history of the bearing is written in the metallurgy.

Preventing failure is vital to maintaining reputation, saving costs and time, saving lives, or simply avoiding inconvenience. If your bearings do fail, it’s critical to understand the reasons why and how to prevent it from happening again in the future.

At LILY Bearing, our experience speaks volumes. The expertise we have built up over the years makes us a go-to source for bearing failure analysis across a number of industries and applications. We serve a wide range of industries, including:

- Commercial airframes

- Power plants

- Space

- Nuclear

- Cryogenics

When these businesses confront bearing failure, they know to come to LILY to determine the cause of the problem and offer solutions to fix and mitigate future problems. We assist by providing users with knowledge and expertise on failure modes. We also provide access to our testing facilities and specialist equipment to ensure customers avoid any types of inconvenience or unwanted costs that failed bearings can cause.

Types And Causes Of Bearing Failure

INADEQUATE LUBRICATION

Correct lubrication is vital to preserving the life of the bearing. If you conduct a visual inspection and notice discolored grease or smell a burnt odor, it could indicate poor lubrication, which often leads to bearing failure. If lithium-based grease is used, the surface may be so brittle that even light taps with a sharp instrument can shatter it. If the bearing is running in an oil bath and fluid isn’t reaching the races efficiently enough, they could become dry to the touch or possibly blued. Any of the above warning signs will require in-depth examination as soon as possible.

MISALIGNMENT

If one side of any bearing is even slightly misaligned in relation to the other, the path of the rollers or balls will run to one side of the race from the other. This will occur on around half of the circumference of the non-rotating surface. The rotating ring is also very likely to have a wider roller path, which commonly results in frictional forces that produce a high enough temperature to affect efficiency or cause lubrication issues.

CONTAMINATION

One of the most common causes of bearing failure stems from contaminations. The cause of these failures is usually due to the presence of foreign objects inside the bearing. In the majority of cases, contamination will leave visible marks like pitting, scoring, or scratches. However, visual inspection cannot always determine whether contamination has occurred, especially if the environment of operation is one where fine mists of fluids or dust particles are commonly present. LILY can provide insight into which bearings suit each type of environment. We can also provide consistent testing to ensure the longevity of your bearings and applications. Failure prevention costs less than replacements.

ELECTRICAL ARCING

Regardless of whether it is caused by adjacent component failure or simply a build-up of static charge, electric arc erosion happens when a current passes through a bearing and its contact point between the races and rollers. This can result in adversely high temperatures on certain parts of the bearing, which could then cause surface pitting on the contacting faces. Our team can advise on how these mishaps can be avoided.

CAGE DAMAGE

Your bearing(s) cage can be damaged in numerous ways. Some of the most common include a lack of lubrication, excessive vibration, or wear and overspending. If you are experiencing cage damage, contact us and we can help you find the most effective solution.

BRINELLING

Brinelling is damage that is caused to the raceway. The most common cause for this kind of damage is incorrect installation or replacement of a bearing, or when too much thrust force has been applied, intentionally or not. Visually, you can spot brinelling by the small indentations on the race, which aligns to the location of the balls. Users need to be aware that one direct cause of brinelling could be hammer blows to the bearing, or a shock load on a static shaft. LILY can assist in advising how to identify causes of brinelling and help you to reverse the damage.

FALSE BRINELLING

False brinelling is caused by vibrations in a static bearing. It could potentially be caused by a machine in which the bearing is being installed, but can sometimes also be caused during the transportation of equipment. Users should look out for indentations on the axial and circumferential components of the raceways. The indentations can appear very similar to brinelling. However, false brinelling is characterised by the degradation of the material from a combination of both chemical and mechanical action.

FATIGUE FAILURE

Fatigue failure results from a weakening in the grain of the bearing steel. This type of damage can be visually identified by flaking of the raceway. However, fatigue failure begins beneath the surface before migrating to the raceway, so is invisible to the eye early on. This can be normal near to the end of the life of a bearing, though fatigue failure can occur at any time due to excessive loads being applied. LILY can assist during the design stage to ensure that your bearing(s) will truly hold up to the projected static and dynamic loads that are projected, thus preventing fatigue failure.

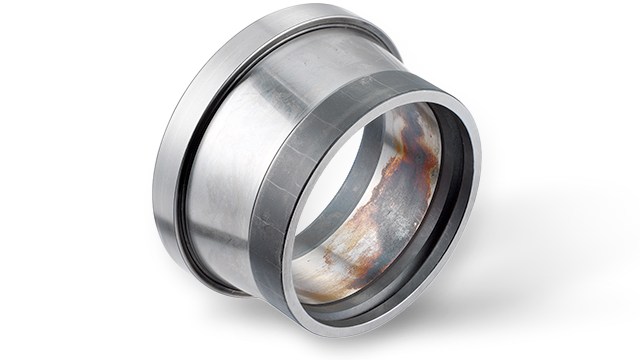

RACEWAY WEAR

Examining the wear path pattern in a bearing that’s been removed from its service can give you an idea of the operating conditions that the bearing came under. By establishing the difference between normal and abnormal wear on a pathway, we can identify whether the bearing has been used properly or not.