Cancel

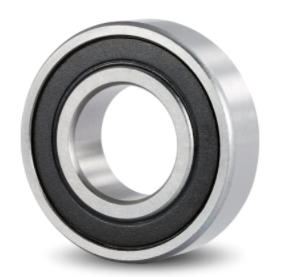

S316-6324

| Part Number | S316-6324 |

| System of Measurement | Metric |

| Bearing Type | Ball |

| For Load Direction | Radial |

| Seal Type | Open |

| Bore Dia | 120 mm |

| Outer Dia | 260 mm |

| Width | 55 mm |

| Ring Material | 316 Stainless Steel |

| Ball Material | 316 Stainless Steel |

| Cage Material | 316 Stainless Steel |

| Dynamic Radial Load | 18704 lbf |

| Static Radial Load | 16726 lbf |

| Max Speed (X1000 rpm) | 1.70 |

| Temperature Range | -86 to 230 °F |

| Weight | 6350 g |

Design Features of S316-6324 Bearing

S316-6324 Bearing is a precision-engineered component designed to offer a blend of high-performance and robustness. S316-6324 bore dia is 120 mm. Its out dia is 260 mm. S316-6324 width is 55 mm. Crafted from AISI316L stainless steel, this bearing boasts enhanced corrosion resistance, making it well-suited for applications in challenging and damp environments.

What Benefits Can S316-6324 Bearing Provide?

- High Corrosion Resistance: Especially effective against pitting and crevice corrosion in chloride environments.

- Durability: Comparable strength to other austenitic steels, but with enhanced longevity in corrosive conditions.

- Excellent Weldability and Formability: Easier to fabricate and weld without losing corrosion resistance.

- Hygienic Material: Easy to clean, making it suitable for sanitary conditions.

- Aesthetic Appeal: Maintains a clean, bright surface even in harsh conditions.

What Can S316-6324 Bearing Be Used for?

S316-6324 Bearing is tailored for specific applications, such as:

- Machinery: Ideal for equipment using Imperial measurement systems.

- Marine Environments: Suited for conditions with moisture and salinity due to corrosion resistance.

- Chemical Processing: Preferred in chemical industries for their resilience against corrosive substances.

- Food & Beverage Processing: Compliant with hygiene standards, reducing contamination risk.

- Medical and Pharmaceutical Equipment: Valuable for withstanding sterilization processes and resisting corrosion.

Recommended Products

})