Cancel

CE3208ZRPP

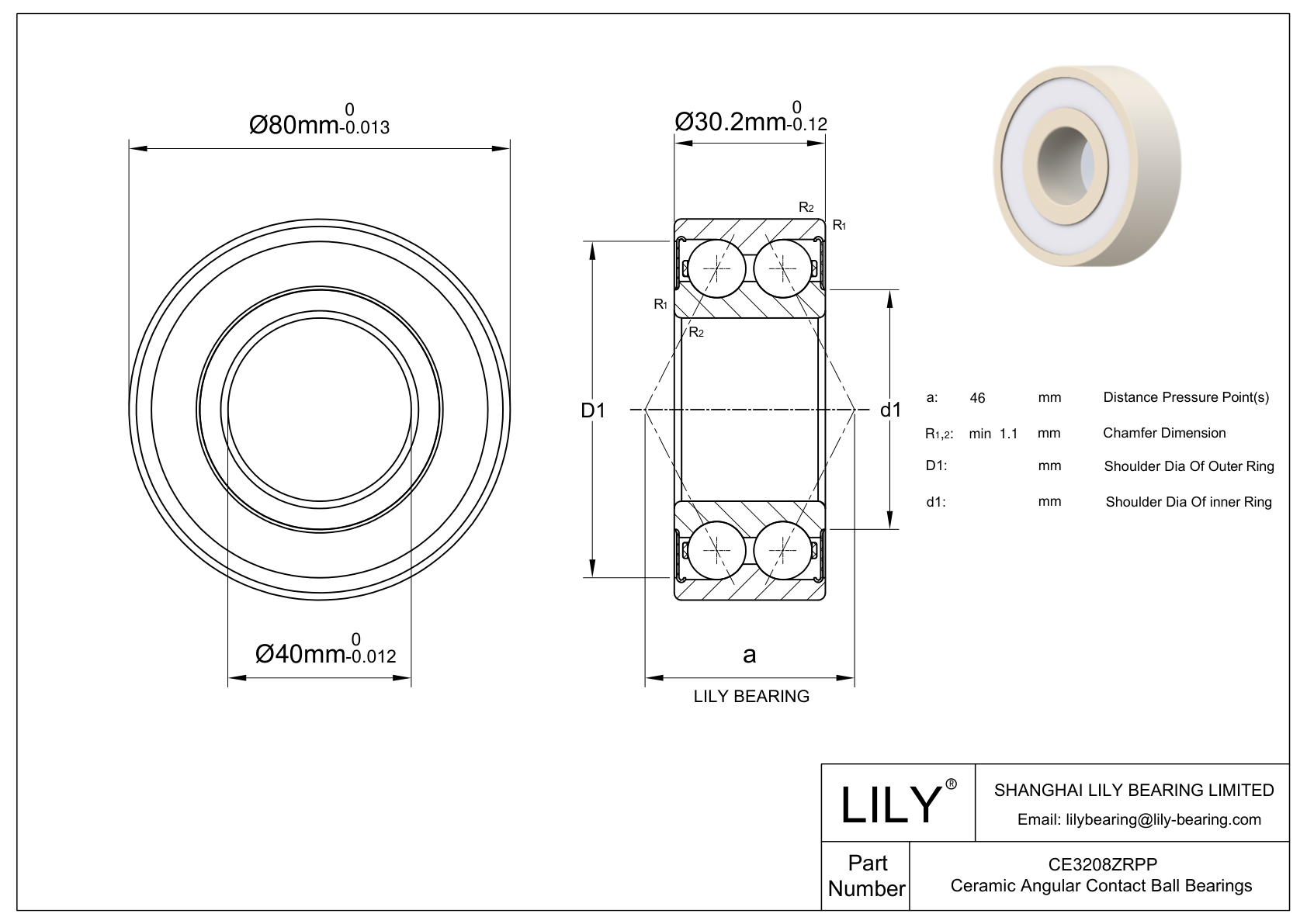

| Part Number | CE3208ZRPP |

| System of Measurement | Metric |

| Bearing Type | Ball |

| For Load Direction | Angular Contact |

| Construction | Double Row |

| Seal Type | Sealed |

| Bore Dia | 40 mm |

| Bore Dia Tolerance | -0.012 mm to 0 |

| Outer Dia | 80 mm |

| Outer Dia Tolerance | -0.013 mm to 0 |

| Width | 30.2 mm |

| Width Tolerance | -0.12 mm to 0 |

| Chamfer Dimension (r1 2)(min) | 1.1 mm |

| Distance Pressure Point (a) | 46 mm |

| Ring Material | Zirconia |

| Balls Material | Zro2 |

| Cage Material | PEEK |

| Dynamic Radial Load | 2914 lbf |

| Static Radial Load | 2216 lbf |

| Max Speed (X1000 rpm) | 5.23 |

| Lubrication | Dry |

| Temperature Range | -176 to 752 °F |

| ABEC Rating | ABEC-1 |

| ROHS | Compliant |

| REACH | Compliant |

| Weight | 0.43 kg |

Design Features of CE3208ZRPP Bearing

CE3208ZRPP Bearing is engineered for demanding applications that require high precision and robust load handling. This bearing is notable for its use of zirconia (ZrO2) ceramic balls and a double-row arrangement, enhancing both performance and durability. CE3208ZRPP bore dia is 40 mm. Its out dia is 80 mm. CE3208ZRPP width is 30.2 mm. It offers an excellent solution for applications that demand high durability, load capacity, and precision.

What Benefits Can CE3208ZRPP Bearing Provide?

- Higher Load Capacity: Ideal for demanding applications with enhanced axial and radial load handling.

- Superior Durability: Zirconia provides exceptional wear resistance, increasing the bearings' lifespan.

- Corrosion Resistance: Suitable for harsh environments due to excellent resistance to corrosion.

- Thermal Stability: Reliable performance across a wide temperature range.

- Electrical Insulation: Non-conductive, ideal for electrically sensitive applications.

- Stability and Rigidity: The double-row design ensures greater stability and rigidity in high-load situations.

What Can CE3208ZRPP Bearing Be Used for?

CE3208ZRPP Bearing is suitable for applications such as:

- Heavy Industrial Machinery: Ideal for handling high axial and radial loads in manufacturing and heavy machinery.

- Aerospace Components: Essential for precision and stability in aircraft systems and satellite components under high-load conditions.

- Chemical Processing Equipment: Perfect for use in corrosive environments, offering reliability and resistance to chemical degradation.

- High-Performance Automotive Systems: Suitable for racing and luxury vehicles where endurance and load-bearing capacity are crucial.

- Medical Devices: Used in advanced medical machinery like MRI machines, where high precision and stability are necessary in demanding conditions.

Recommended Products

})