Single Row Tapered Roller Bearings from LYC & Wind Turbine Field

Not long ago, LYC developed a set of 16 MW platform wind power spindle bearings. The bearings been the largest powered wind power spindle bearings in China at present. The high-power bearings put strict requirements on the bearing manufacturing enterprises. They need high-performance materials in the case of larger sizes. They also need to ensure the reliability and the lifespan under the condition of increased radial force and axial force with increased radial and axial forces. From the perspective of bearing science, the bearings developed by LYC are a kind of Single Row Tapered Roller Bearings.

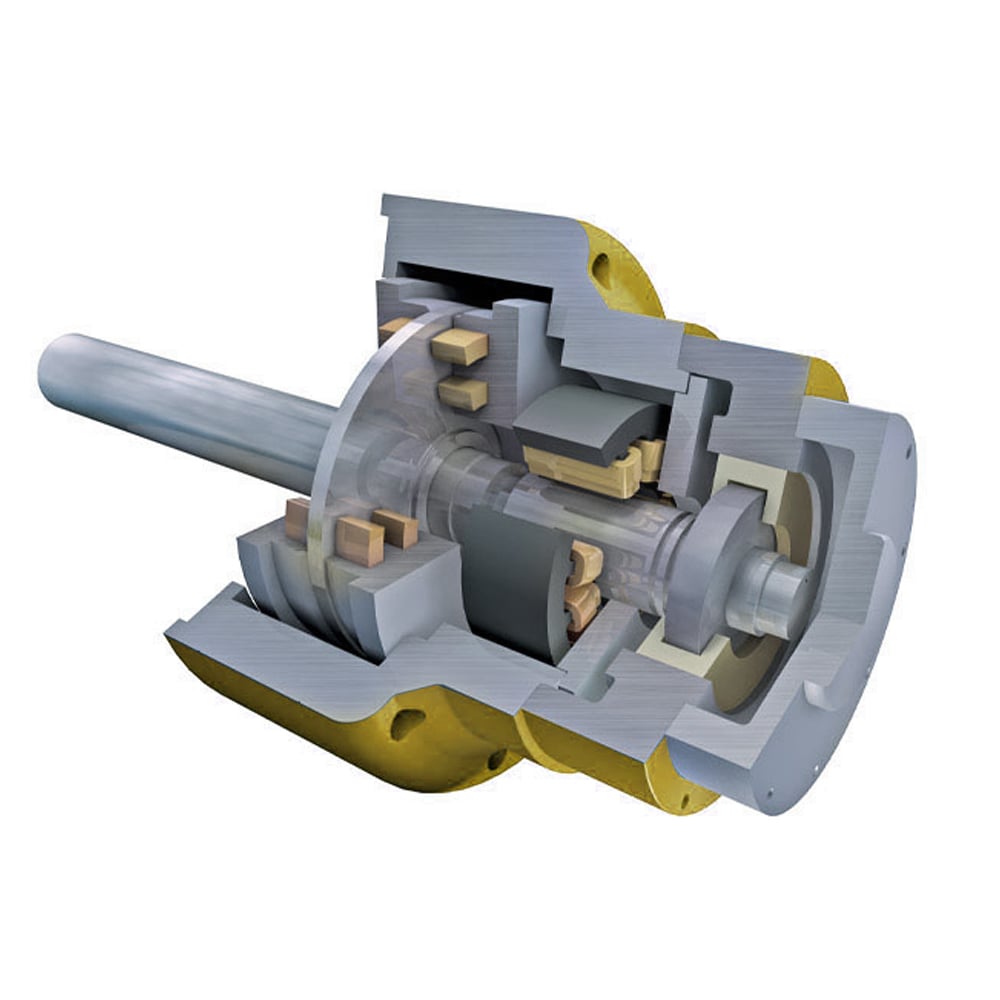

From the structural point of view, Single Row Tapered Roller Bearings belong to separated bearings. The main structure includes the inner ring, the outer ring and a number of rolling bodies. The inner and outer rings of Single Row Tapered Roller Bearings are tapered, and the inner ring is tightly attached to the shaft. Rolling bodies of Single Row Tapered Roller Bearings, that is, tapered rollers, are arranged in a certain order between the inner and outer raceways. They are kept in a proper position with the help of the cage. The tapered rollers taper toward the outer end and they roll between the inner and outer rings.

According to the the working principle, tapered roller bearings with single row are the mainstay of parts in the modern machinery. Because the shape of the roller is tapered, the projection lines of the tapered surface are gathered at the same point of the bearing axis. This shape can ensure that the rollers do not slide irregularly on the raceway, but follow a predetermined path to achieve perfect motion on the raceway. Actually, Single Row Tapered Roller Bearings are mainly used to bear not only the radial loads but also a kind of combined radial and axial loads. The axial load of Single Row Tapered Roller Bearings is mainly determined by the contact angle. The contact angle is the angle between the roller and the raceway contact. When the contact angle increases, the axial load will increase. The opposite is true. The contact angle can ensure that the rollers are able to roll easily in both directions.

During the R&D stage of Single Row Tapered Roller Bearings, LYC made full use of its industry-leading R&D and manufacturing advantages as well as its user experience. Experts of LYC studied the raw material selection, the product design and the process manufacturing. In addition, they adopted various means such as a kind of means called the finite element analysis. And finally LYC made big breakthroughs in the heat treatment, the machining process, the cage manufacturing, the surface coating and so on.

These unique Single Row Tapered Roller Bearings developed by LYC have unique advantages.

(1) High level of load capacity

The Single Row Tapered Roller Bearings have linear contact characteristics. This feature can reduce the contact stress of rollers and raceways, and thus ensure a high level of load capacity. Single-row tapered roller bearings also have a composite load capacity, which can withstand loads that other bearings cannot, and can bear extremely high radial and axial loads at the same time.

(2) Self-aligning function & The ability to adapt to the misalignment

For the wind turbine main shaft, the tapered structure of the rollers can determine that the Single Row Tapered Roller Bearings can have higher speed limit and self-aligning ability as well as excellent ability to adapt to misalignment.

(3) High durability

As is known, the wind turbine equipment are basically exposed to the long-term harsh working conditions. The main shaft of the wind turbine need bearings with the high durability. Single Row Tapered Roller Bearings are extremely strong and have a high degree of durability, thus requiring less maintenance costs. As has been proved many times, some models of Single Row Tapered Roller Bearings from Lily Bearing, such as A2031-A2126, LM12749-LM12710, are also good cases in point.

(4) High value of use

In terms of the value, small rollers can withstand great loads. Meanwhile, Single Row Tapered Roller Bearings have a longer service life, and can also meet the additional needs of clients. All this can reduce the cost of maintenance and repair. Furthermore, tapered single roller bearings can compensate for the side effects of thermal expansion through the adjustment of clearance.

Single Row Tapered Roller Bearings under preload can provide sufficient stiffness and accuracy. Therefore, for these bearings, very tight tolerances can be made. Single Row Tapered Roller Bearings can also be adjusted by a small torque and their operation noises are low.

(5) Low friction

Single Row Tapered Roller Bearings are optimized in the roller design and the surface finish of flange, which can contribute to the formation of the lubricant film. The lubricating oil film can reduce the friction, thus reducing the wear on the flange. Through this way, Single Row Tapered Roller Bearings can be well protected and can be in good operation.

The successful launch of LYC 16 MW platform wind turbine spindle bearing can demonstrate its unique technology. The special Single Row Tapered Roller Bearings broke a record of China's high-power wind turbine spindle bearings. The successful invention became a milestone in the development of China's wind turbine bearing field. It played a great role in promoting the development of China's wind power industry. With it, China's wind power products can effectively response to the climate change as well as the energy security.

CATEGORIES

- Miniature Bearings(2)

- Thin Section Bearings(1)

- Ceramic Bearings(7)

- Stainless Steel Bearings(3)

- Needle Roller Bearings(3)

- Spherical Roller Bearings(1)

- Thrust Ball Bearings(2)

- Roller Bearings(1)

- Tapered Roller Bearings(2)

- Slewing Ring Bearings(2)

- Angular Contact Ball Bearings(1)

- Sleeve Bearings(1)

- Others(44)

- Low Temperature Bearings(1)

- Ball Bearings(9)

- Bearing Load(4)

- Bearing Components(1)

- Types of Bearings(4)

- Thrust Bearings(1)

- Bearing Technical Knowledge(20)

- Aerospace Bearings(2)

- Polyurethane Rollers(2)

- Cam Follower(3)

- Linear Bearings(1)

- Spherical Bearings(1)

LATEST ARTICLES

-

The Impact of Counterfeit Bearings On the Industry and How to Avoid Them

The Impact of Counterfeit Bearings On the Industry and How to Avoid Them -

Chrome Steel vs. Stainless Steel Bearings: Which Do You Need?

Chrome Steel vs. Stainless Steel Bearings: Which Do You Need? -

Magnetic Bearings: What They Are & How They Work

Magnetic Bearings: What They Are & How They Work -

Expert Tips On Installing & Removing Bearings for Industry Professionals

Expert Tips On Installing & Removing Bearings for Industry Professionals -

How Much Grease to Put in Bearings: A Comprehensive Guide

How Much Grease to Put in Bearings: A Comprehensive Guide -

How to Clean Ceramic Bearings?

How to Clean Ceramic Bearings?