Transforming Food Packaging: A Deep Dive into Stainless Steel Needle Roller Bearings

In the demanding realm of food processing and packaging, every component's efficiency and reliability are critical for operational success and health safety. Industrial bearings, in particular, play a pivotal role in these systems. This case study from Lily Bearing showcases how stainless steel needle roller bearings have revolutionized a client's food packaging machinery, enhancing both performance and durability.

Deep Groove Ball Bearings: The Initial Challenge

Initially, the client’s packaging machinery utilized deep groove ball bearings. These bearings are known for their versatility and are typically used in applications with moderate loads and speeds. However, they encountered limitations in load capacity during operation, prompting the need for an alternative solution.

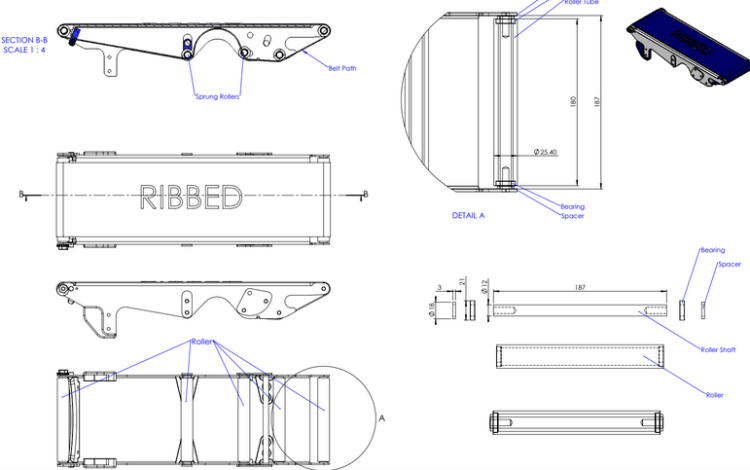

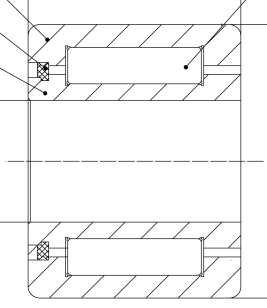

Structure Diagram of the Client’s Original Deep Groove Ball Bearing Solution

Advantages of Needle Roller Bearings

To address these challenges, Lily Bearing’s engineers recommended switching to needle roller bearings. These bearings offer several distinct advantages:

- High Load Capacity and Compactness: Despite their small size, needle roller bearings have a high load capacity. This is due to their design, where the surface area in contact with the raceway is large, allowing them to support heavier loads compared to other types of bearings of similar size.

- Low Friction and High Efficiency: With a low coefficient of friction, needle roller bearings contribute to high transmission efficiency and minimal operational heat, reducing lubricant consumption.

- Compact and Space-Saving Design: One of the most significant advantages of needle roller bearings is their compact design. They have a small cross-sectional height, making them ideal for applications with limited radial space.

- Ability to Withstand Rigorous Conditions: Needle roller bearings are robust and can perform reliably under challenging conditions, including high speeds and temperatures.

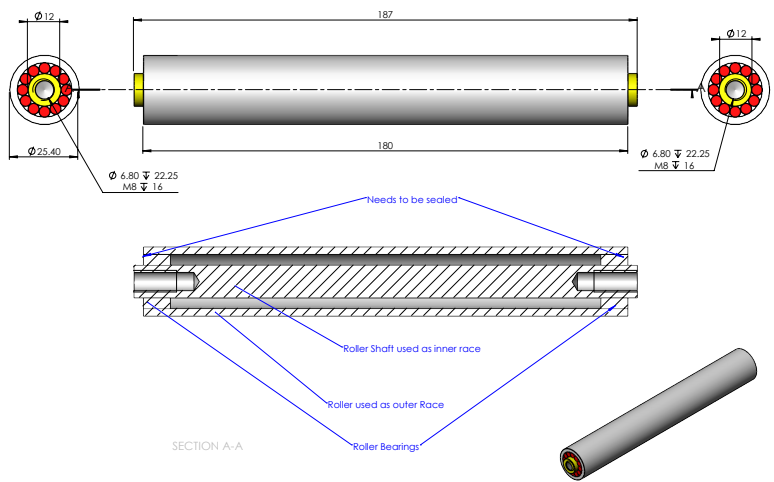

needle roller bearings

Customized Solution of Stainless Steel Needle Roller Bearings

The choice of stainless steel for the needle roller bearings was crucial due to the wet and corrosive nature of the food packaging environment. This material ensured the bearings' longevity and compliance with health standards. The engineering process involved detailed analysis of loads, rotational torques, and bearing structures, ensuring the final product met all operational requirements.

Other Improvements of the Solution

The client initially faced challenges with the deep groove ball bearings used in their equipment, particularly concerning the insufficient hardness of the shafts. In seeking a solution with needle roller bearings, they emphasized the need for enhanced shaft hardness and a mechanism to protect the shaft. Additionally, the client highlighted constraints in mounting space, which limited the use of shims and led to issues with the inner ring sliding unpredictably.

In response to these specific requirements, Lily Bearing's engineering team embarked on a tailored design approach for the needle roller bearings.

Shaft Hardness Optimization: They focused on optimizing the shaft hardness to ensure it met the rigorous demands of the machinery.

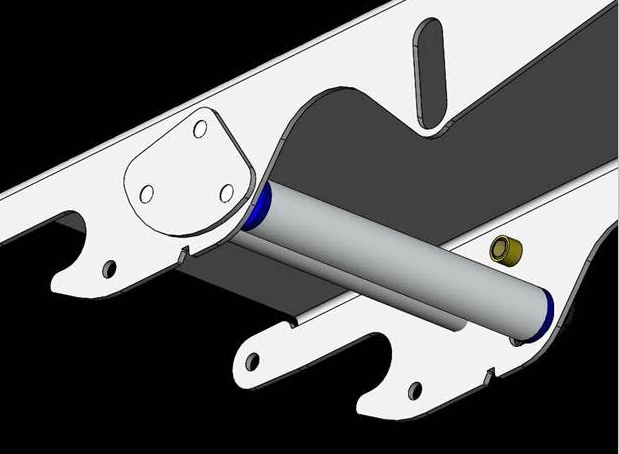

- Innovative Spacer Design: To address the sliding issue, the engineers innovatively designed the shafts with a unique spacer configuration. They strategically placed a spacer on one side to prevent the inner ring from sliding, while leaving the other side without spacers. This design not only resolved the sliding problem but also provided an easy access point for lubricant addition, enhancing the overall functionality and maintenance ease of the bearings.

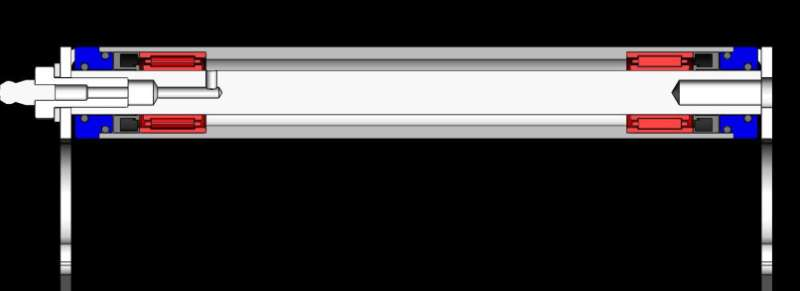

Design drawings of the solution of needle roller bearings

Installation drawing of the solution of needle roller bearings

Installation drawing of the solution of needle roller bearings

Client Satisfaction and Long-term Partnership

The client reported a marked improvement in the machinery's performance with the new needle roller bearings. This led to a significant order and an interest in establishing a long-term partnership with Lily Bearing, highlighting the value of customized bearing solutions in specialized machinery.

Conclusion

The transition from deep groove ball bearings to customized stainless steel needle roller bearings by Lily Bearing underscores the importance of selecting the right bearing for specific machinery needs. This case study illustrates how custom engineering solutions can significantly improve the efficiency and reliability of food packaging operations, contributing to overall machinery performance and safety standards in the food processing industry.

Keep Learning