How To Measure Needle Bearing Dimensions And Choose The Correct Bearing Type

It's important to measure needle bearing dimensions and choose the correct bearing type when designing a new system, replacing a damaged bearing, upgrading an existing system, or changing the application of a system. Choosing the right needle bearing ensures proper fit and function, improves efficiency, and prolongs the system's lifespan. In this article, we will explain how to measure needle bearing dimensions and choose the correct bearing type. Let’s follow the steps below.

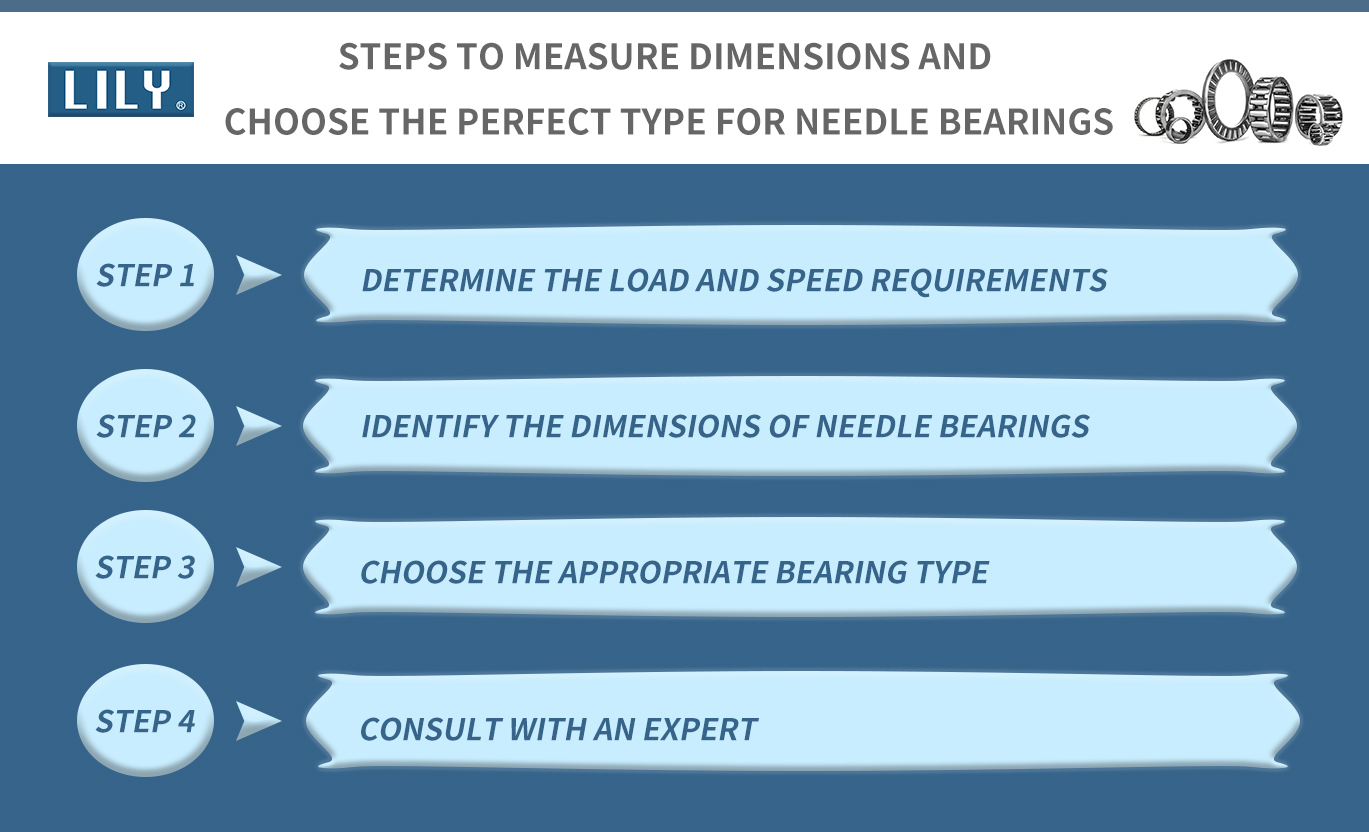

Step 1: Determine the Load and Speed Requirements

Before measuring needle bearing sizes and choosing the correct bearing type, it is crucial to recheck and determine the load and speed requirements. This helps to select a proper needle bearing that can handle the specific requirements of the system and ensures proper function, longevity, and efficiency. For example, a high-speed application will require a needle bearing that can handle the high rotational speeds without excessive heat buildup or wear. Similarly, an application with a heavy load will require a larger needle bearing to support the weight without prematurely failing.

Step 2: Measure the Needle Bearing Sizes

Once you know the load and speed requirements, you'll need to identify the bearing dimensions. About how to measure bearing sizes, here are common ways:

1. The Reference Number

The quickest way to determine the correct type is to use the reference number. Most needle bearings have these numbers engraved on them, but over time they may become difficult to read or rub off completely. In these cases, you'll need to measure the bearing yourself to get an accurate match.

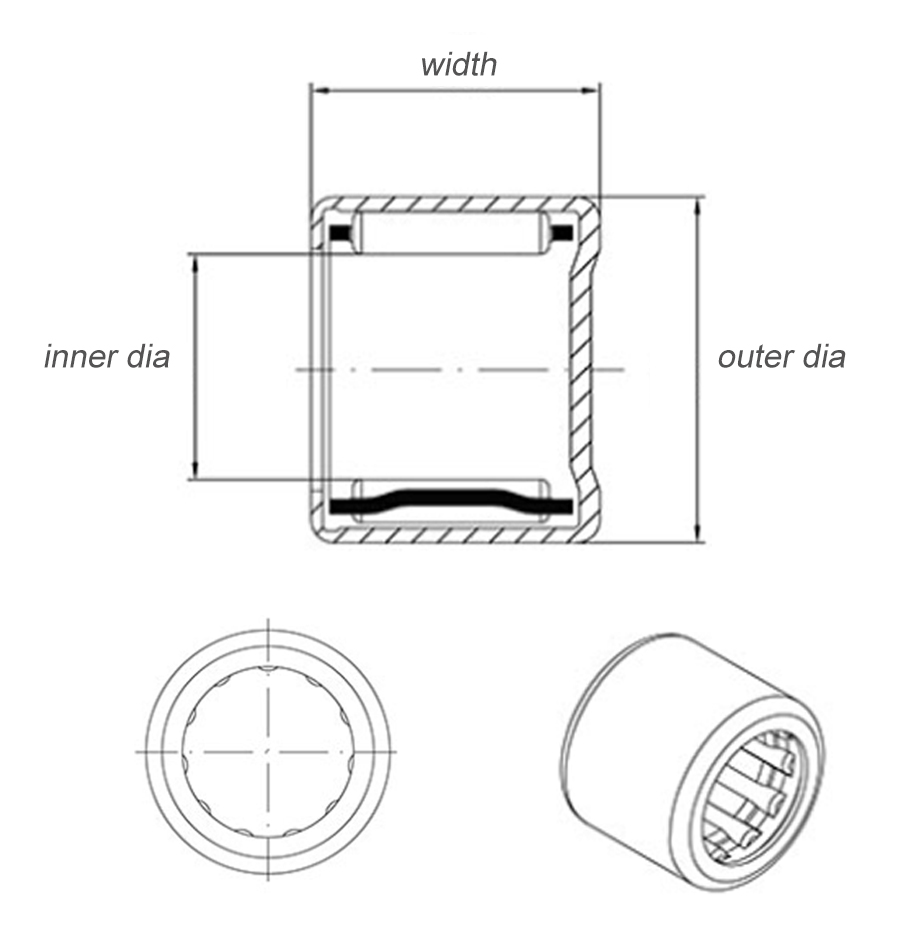

2. Accurate measurement of needle bearings

To measure a needle bearing in a good way, you'll need to determine its width(W), inner diameter(ID), and outside diameter(OD). To get an accurate reading, measure at the widest point for OD and measure at the narrowest point for ID and measure W between the two bearing rings. You can do this with a vernier caliper or a ruler, making sure to measure with precision. Once you have these measurements, you can use our bearing search tool to do bearing search by dimensions.

Step 3: Choose the Appropriate Needle Bearing Type

There are several needle bearing types available. Each type is designed for a specific application, so it's important to choose the appropriate type for your needs. Once you measure your needle bearings, you can use our search to find the corresponding bearing type. This is known as the suffix in the bearings reference.

e.g. Inside Diameter: 12mm; Outside Diameter: 18mm; Width: 16mm - Bearing Type: HK1216

But that's not all – needle roller bearings also have suffixes indicating the presence of seals.

E.g. 2RS= 2 Rubber Seals=double seal

Another important suffix to consider is the bearing clearance value. This determines the amount of room between the bearing races and can affect how the bearing performs in certain conditions. This clearance is necessary to accommodate any thermal expansion that may occur during operation, as well as to ensure that the bearing operates smoothly and efficiently. For example, if a bearing is likely to get hot, a larger clearance may be necessary to allow for heat expansion.

C2 = Clearance is less than international standard

No Markings = Standard Clearance

C3 = Clearance is greater than international standard

C4 = Clearance is greater than C3

It is important to choose the correct clearance for a needle bearing based on the application requirements. Too much clearance can cause the needle bearing to vibrate excessively, while too little clearance can cause the bearing to overheat and fail prematurely.

Step 4: Consult with an Expert

If you're still unsure about how to measure needle bearing dimensions and choose the perfect bearing type, don't hesitate to consult with an expert. A bearing supplier or engineer can help you based on your specific requirements. At LILY Bearing, we are committed to provide the best services about bearings. Contact us today to learn more about how we can meet your needle bearing needs.

CATEGORIES

- Miniature Bearings(2)

- Thin Section Bearings(1)

- Ceramic Bearings(7)

- Stainless Steel Bearings(3)

- Needle Roller Bearings(3)

- Spherical Roller Bearings(1)

- Thrust Ball Bearings(2)

- Roller Bearings(1)

- Tapered Roller Bearings(2)

- Slewing Ring Bearings(2)

- Angular Contact Ball Bearings(1)

- Sleeve Bearings(1)

- Others(44)

- Low Temperature Bearings(1)

- Ball Bearings(9)

- Bearing Load(4)

- Bearing Components(1)

- Types of Bearings(4)

- Thrust Bearings(1)

- Bearing Technical Knowledge(19)

- Aerospace Bearings(2)

- Polyurethane Rollers(2)

- Cam Follower(3)

- Linear Bearings(1)

- Spherical Bearings(1)

LATEST ARTICLES

-

Chrome Steel vs. Stainless Steel Bearings: Which Do You Need?

Chrome Steel vs. Stainless Steel Bearings: Which Do You Need? -

Magnetic Bearings: What They Are & How They Work

Magnetic Bearings: What They Are & How They Work -

Expert Tips On Installing & Removing Bearings for Industry Professionals

Expert Tips On Installing & Removing Bearings for Industry Professionals -

How Much Grease to Put in Bearings: A Comprehensive Guide

How Much Grease to Put in Bearings: A Comprehensive Guide -

How to Clean Ceramic Bearings?

How to Clean Ceramic Bearings? -

Silicon Nitride Balls: Revolutionizing Precision Bearings

Silicon Nitride Balls: Revolutionizing Precision Bearings