How to Judge Quality Bearings

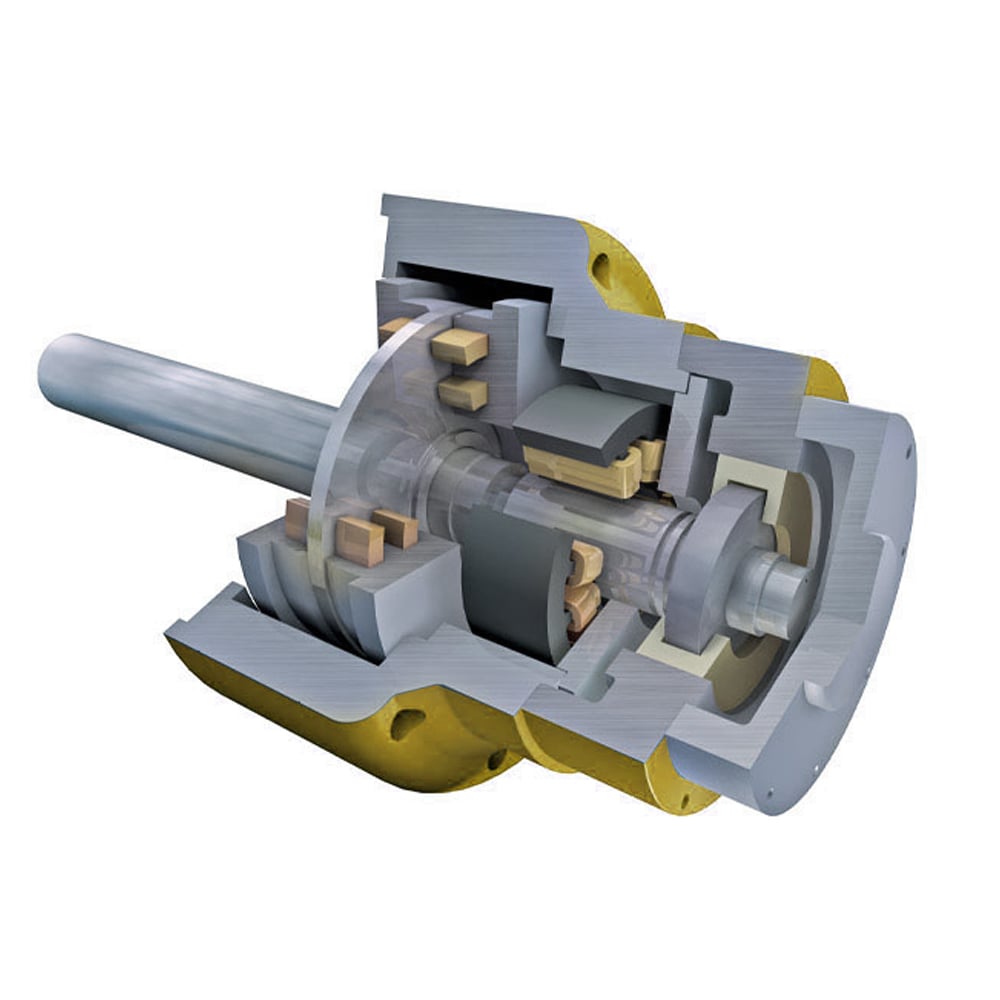

Bearings are crucial components in mechanical equipment, with precision, performance, and reliability determining the mainframe's output. The quality of bearings directly affects the efficiency and lifespan of machinery. High quality bearings reduce friction and increase equipment service life, while low quality bearings cause troubles and hinder performance. As quality standards increase, the bearing industry must continuously upgrade products and innovate technology to meet demands. However, the public generally lacks knowledge of bearings due to their status as fast-moving consumer goods. To improve understanding, we consulted with Chinese bearing experts on bearings' structure, sizes, and performance and how to judge quality bearings.

Check the Manufacturer's Reputation

One of the most important factors in choosing quality bearings is the reputation of the manufacturer. A reputable manufacturer will use high-quality materials and advanced production techniques to produce bearings that meet or exceed industry standards. To ensure optimal machinery performance and production safety, purchase high quality bearings from reputable sources. Choosing cheaper options may lead to machinery breakdowns and increased costs in the long run.

Bearing manufacturers that comply with industry standards and regulations typically have certifications to prove it. Look for certifications such as ISO 9001 or the European Union's CE marking. Compliance with industry standards and regulations is an indication of a manufacturer's commitment to quality.

Examine the Packaging

Bearing quality can also be judged by examining the packaging. High quality bearings are typically packaged in clean, sturdy containers that protect them from damage during transportation and storage. The packaging should also include clear labeling and instructions for use.

Check the Bearing's Finish and Texture

The finish and texture of the bearing can provide clues about its quality. High quality bearings will have a smooth, even finish, and a consistent texture. In contrast, a low-quality bearing may have rough edges, burrs, or uneven surfaces.

Rigidity is an Important Index

Rigidity refers to the power required for bearings to produce unit deformation. Rolling bearings have short elastic deformation and can be unconsidered in many types of equipment. However, in equipment such as machine tool principal axis, it is an important factor. Cylindrical and tapered roller bearings are ideal for supporting loads with rolling elements and rollaway nests.

Consider the Shaft Size When Selecting Bearings

When designing machines, it is important to consider the size of the axis first and then choose bearings accordingly. Ball bearings are suitable for small shafts, while roller bearings are ideal for large shafts. Needle roller bearings, extra-light, and ultra-light series of ball or roller bearings can be used to increase flexibility in machines with restricted diametric directions. Narrow or extra-narrow series of quality bearings with balls and rollers are ideal for machines with axial location restrictions.

Installation and Removal Convenience is Key

When selecting quality bearings, it is crucial to consider how easy they are to install and remove. This is particularly important for large and oversize bearings. Angular contact ball bearings, tapered roller bearings, cylindrical roller bearings, and needle roller bearings are easy to install and remove because their inner race can be set on the shaft and in the housing bore. Spherical roller bearings, double row cylindrical roller bearings, and spherical ball bearings with inner diameter tapered bore are also easy to install and remove.

Test the Bearing's Durability and Load Capacity

The load is an essential consideration when selecting bearings. Roller bearings are ideal for supporting heavy loads, while ball bearings are better suited to lighter or medium loads. Quality bearings made of carburizing steel or with Bainite quenching can support vibratory shock loads. Choosing the correct bearings based on load factors is essential for safety and durability in industrial manufacturing.

Finally, you can evaluate quality bearings by testing their durability and load capacity. You can perform tests such as the rolling contact fatigue test, the impact test, or the load capacity test to determine how well the bearings will perform under real-world conditions.

Conclusion

Choosing quality bearings for your machinery is essential for optimal performance, increased service life, and reduced maintenance costs. By considering the application requirements, shaft size, rigidity, installation and removal convenience, load factor, and purchasing high quality bearings from reputable sources, you can ensure the best performance and longevity for your equipment.

CATEGORIES

- Miniature Bearings(2)

- Thin Section Bearings(1)

- Ceramic Bearings(7)

- Stainless Steel Bearings(3)

- Needle Roller Bearings(3)

- Spherical Roller Bearings(1)

- Thrust Ball Bearings(2)

- Roller Bearings(1)

- Tapered Roller Bearings(2)

- Slewing Ring Bearings(2)

- Angular Contact Ball Bearings(1)

- Sleeve Bearings(1)

- Others(44)

- Low Temperature Bearings(1)

- Ball Bearings(9)

- Bearing Load(4)

- Bearing Components(1)

- Types of Bearings(4)

- Thrust Bearings(1)

- Bearing Technical Knowledge(19)

- Aerospace Bearings(2)

- Polyurethane Rollers(2)

- Cam Follower(3)

- Linear Bearings(1)

- Spherical Bearings(1)

LATEST ARTICLES

-

Chrome Steel vs. Stainless Steel Bearings: Which Do You Need?

Chrome Steel vs. Stainless Steel Bearings: Which Do You Need? -

Magnetic Bearings: What They Are & How They Work

Magnetic Bearings: What They Are & How They Work -

Expert Tips On Installing & Removing Bearings for Industry Professionals

Expert Tips On Installing & Removing Bearings for Industry Professionals -

How Much Grease to Put in Bearings: A Comprehensive Guide

How Much Grease to Put in Bearings: A Comprehensive Guide -

How to Clean Ceramic Bearings?

How to Clean Ceramic Bearings? -

Silicon Nitride Balls: Revolutionizing Precision Bearings

Silicon Nitride Balls: Revolutionizing Precision Bearings