Double-row Needle Roller Bearings Proved a Success

It is known that needle roller bearings have low sectional height and large load capacity. They can help save space. They play a key role in a wide range of applications such as automobiles, motorcycles, printing machines, industrial robots as well as construction machines and so on. The below case is about a kind of successful bearing application in food and beverage machinery.

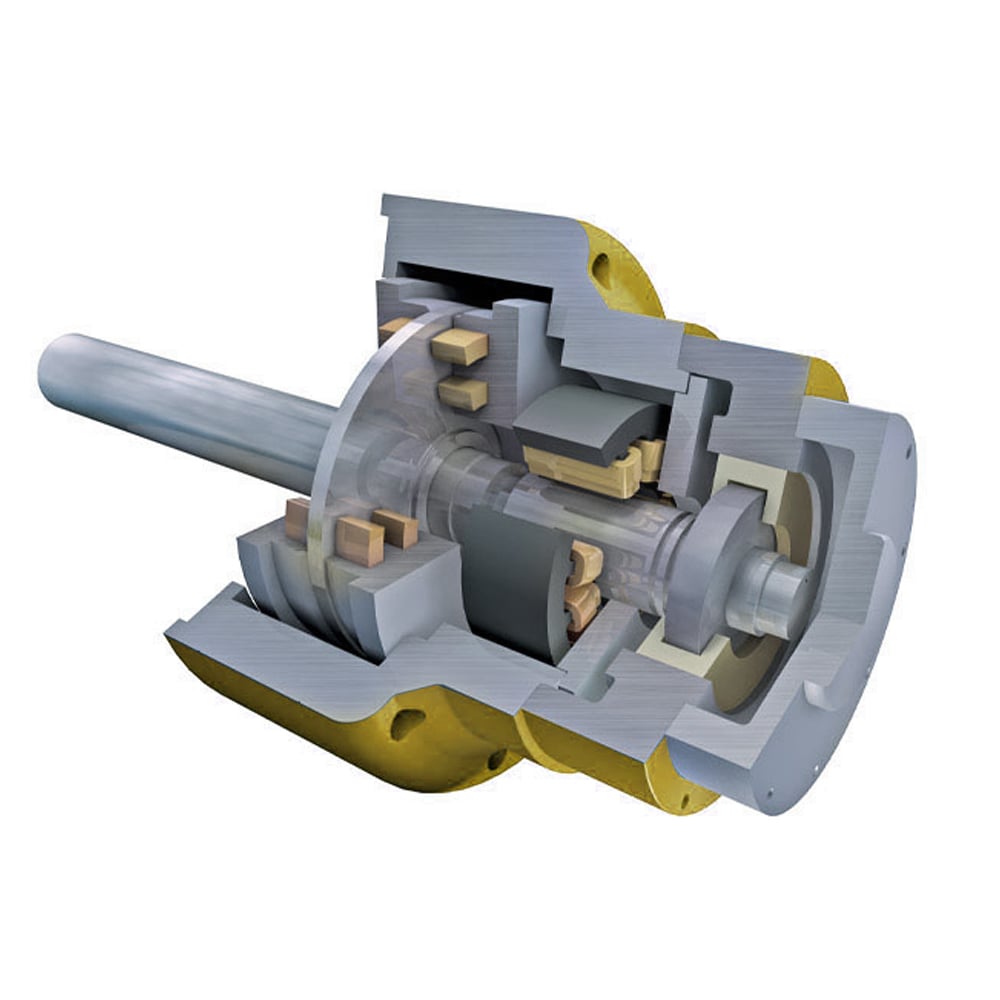

This case shows the importance of innovative ideas about roller bearing solutions. In general, single-row needle roller bearings are commonly used. However, double-row needle roller bearings once provided a brand-new solution. Let’s go to this case and start with the background of the client.

Background of the client

The client is a foreign-owned company which specializes in food and beverage machinery. The company has undergone more than 70 years of reform and development, and it has more than 70 years' experience of food equipment manufacturing. Up till now, this company has a wide range of business. Its business partners are located in nearly every corner of the world. As a worldwide main supplier of food and beverage equipment, the company offers one-stop services for equipment, including process equipment, filling equipment, packaging machines and even material recovery equipment.

Problems encountered

The client originally used needle roller bearings with mechanical equipment. However, after using a period of time, its staff found that the lubrication and load of roller bearings faced great challenges under the pressure of high load operation, because the filling equipment must satisfy the need of high speed and precision requirements. As an important part of the food machinery, the roller bearings will be easy to be damaged and they might even have short life or other defects. This will lead to unstable equipment operation process and decreasing operating efficiency. In addition, the production operation and maintenance costs will increase accordingly. All this needs to be solved in time.

Bearing solutions

According to the actual working conditions of this client, engineers from KIS provided a brand new bearing solution in a professional way. They suggested that the client should replace the original single-row needle roller bearings with double-row needle roller bearings. The reason is that double-row needle roller bearings have compact radial structures and high transmission efficiency.

Furthermore, the design of double-row needle roller bearings can effectively increase the bearing capacity and thus help relieve the client’s anxiety about insufficient load and being prone to be damaged. In addition, its slim rollers can actively reduce the coefficient of friction, which can ensure that lubrication meets expectations. Thus, the efficiency of equipment operation can be improved. Thereby, safety of the production process can be realized.

Good Feedback

The client did the replacement and upgrade for original single-row needle roller bearings according to KIS’s engineers bearing solutions. After the equipment running test for a period of time, the client reflected that under the same working frequency, the probability of bearing problems has been reduced. Furthermore, double-row needle roller bearings are more in line with the actual bearing pressure of the equipment than before. In addition, double-row needle roller bearings can provide higher radial load and high running accuracy. Meanwhile, equipment breakage rate has been reduced and the service life of the equipment has been effectively increased.

In Summary

Double-row needle roller bearings can provide equipment with higher radial load capacity than single-row bearings due to their optimized design of needle rollers and raceways. Double-row needle roller bearings are suitable for the application environment of high load, high precision and so on. At the same time, double-row needle roller bearings can obtain high running accuracy, which is a very good choice in case of limited speeds and installation space.

It is known that food as well as beverage machinery must meet stringent requirements for operation and maintenance cost controlling, improvement of operational efficiency, production safety, etc. In recent years, the safety as well as hygiene of processed food has been facing tough tests. As the main parts of food machinery, proper use of bearings can make efficient and safe production possible. KIS provides services of new technology for each process, including raw material handling equipment, processing equipment, filling systems as well as packaging systems. At the same time, personalized solutions can help food and beverage machinery achieve higher production performance.

CATEGORIES

- Miniature Bearings(2)

- Thin Section Bearings(1)

- Ceramic Bearings(7)

- Stainless Steel Bearings(3)

- Needle Roller Bearings(3)

- Spherical Roller Bearings(1)

- Thrust Ball Bearings(2)

- Roller Bearings(1)

- Tapered Roller Bearings(2)

- Slewing Ring Bearings(2)

- Angular Contact Ball Bearings(1)

- Sleeve Bearings(1)

- Others(44)

- Low Temperature Bearings(1)

- Ball Bearings(9)

- Bearing Load(4)

- Bearing Components(1)

- Types of Bearings(4)

- Thrust Bearings(1)

- Bearing Technical Knowledge(20)

- Aerospace Bearings(2)

- Polyurethane Rollers(2)

- Cam Follower(3)

- Linear Bearings(1)

- Spherical Bearings(1)

LATEST ARTICLES

-

The Impact of Counterfeit Bearings On the Industry and How to Avoid Them

The Impact of Counterfeit Bearings On the Industry and How to Avoid Them -

Chrome Steel vs. Stainless Steel Bearings: Which Do You Need?

Chrome Steel vs. Stainless Steel Bearings: Which Do You Need? -

Magnetic Bearings: What They Are & How They Work

Magnetic Bearings: What They Are & How They Work -

Expert Tips On Installing & Removing Bearings for Industry Professionals

Expert Tips On Installing & Removing Bearings for Industry Professionals -

How Much Grease to Put in Bearings: A Comprehensive Guide

How Much Grease to Put in Bearings: A Comprehensive Guide -

How to Clean Ceramic Bearings?

How to Clean Ceramic Bearings?