Bushing Vs Bearings - Everything You Need to Know

In the world of machinery and mechanical engineering, bearings and bushings are two essential components that are used to support and guide moving parts. However, have you been wondering what the differences between bushings and bearings are? You’re not alone! Many people are confused when it comes to understanding these two important components in machinery operations.

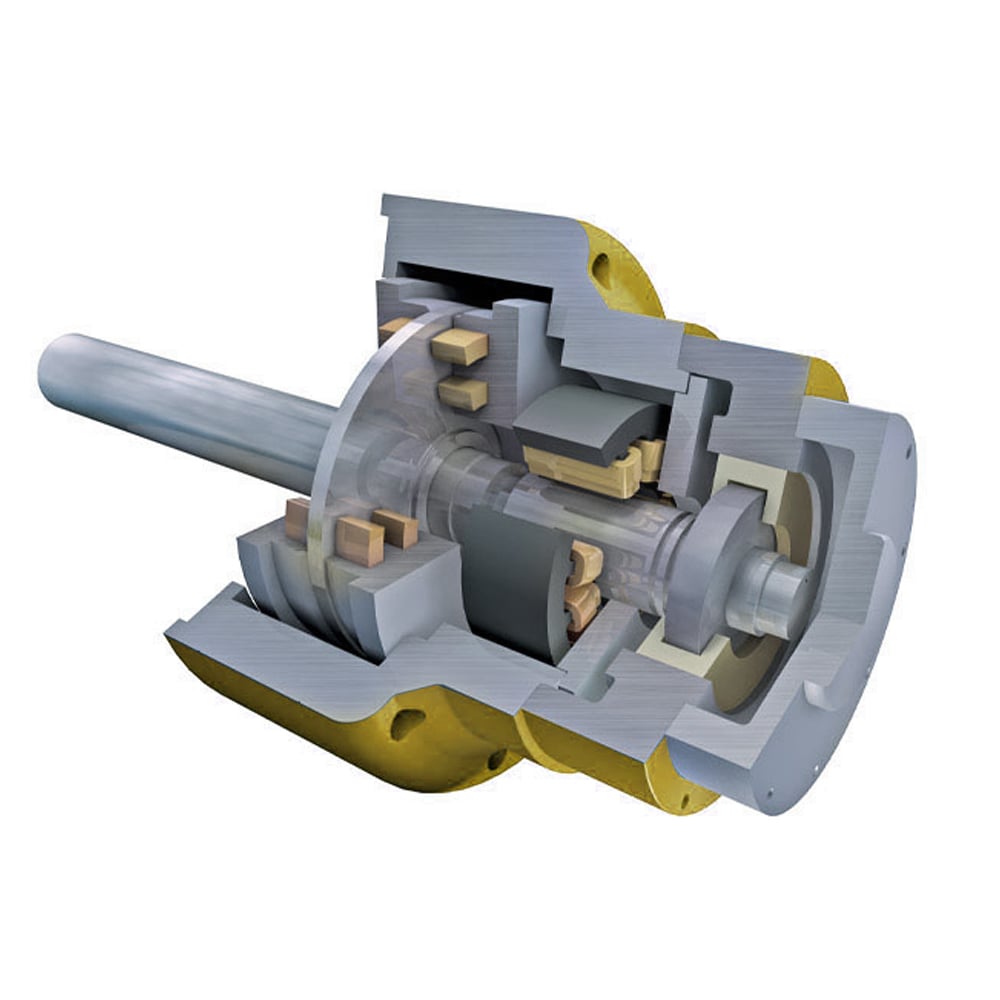

What are bearings?

Bearings come in many different shapes and sizes depending on the application but are generally made from harder materials such as steel or ceramic for better performance at higher speeds. Because bearings are typically constructed from more durable materials, so that they can withstand heavier loads or faster speeds for longer periods of time without wearing down too quickly. This makes them suitable for high-performance applications like motors, pumps, and compressors where long-term operation at very fast speeds is required.

Common Bearings

- Ball Bearings

- Roller Bearings

- Plain Bearings

- Sleeve Bearings

- Flange Bearings

- Thrust Bearings

- Angular Contact Bearings

- Tapered Roller Bearings

- Needle Bearings

- Spherical Roller Bearings

- Cylindrical Roller Bearings

What are bushings?

Bushing, also called Sleeve Bearings, are a kind of cylindrical shell usually made from softer material such as rubber or plastic which can cushion a joint against shock while preventing metal-to-metal contact. They are used to reduce friction between moving parts of machines by absorbing shock and allowing easy rotational movement. Bushings often have grooves cut into their sides that act as lubrication ports for oil or grease which helps them move freely.

The Benefits of Using Bushings and Bearings

Both bushings and bearings offer many benefits. They can improve efficiency due to less friction, reduced noise levels, increase the lifespan of the equipment and improve safety due to shock absorption capabilities. In addition, both of them help protect the axle or the shaft they are applied to from further wear while allowing smooth rotation or movement of parts within the machine.

Which Materials Make the Best Bushings?

While the design may seem uncomplicated, the performance and functionality of a bushing can significantly vary depending on the material it's made of. Bronze bushings offer exceptional durability and a long lifespan, plus resistance to corrosion and deformation. However, they require frequent lubrication during use, making them a higher maintenance option than plastic. On the other hand, plastic bushings are a favored choice due to their low cost, minimal friction, and low-maintenance characteristics. As they're self-lubricating, they're useful for hard-to-reach parts, and since there's no risk of corrosion, they can be employed in damp environments. Let's examine the benefits and drawbacks of plastic as a bearing material.

Common Bushings

- Sleeve Bushings

- Flanged Bushings

- Tapered Bushings

- Spherical Bushings (Rod End Bearings)

- Linear Bushings (Linear Bearings)

- Oil-Impregnated Bushings (Self-Lubricating Bushings)

The Benefits of Using Bushings and Bearings

Both bushings and bearings offer many benefits. They can improve efficiency due to less friction, reduced noise levels, increase the lifespan of the equipment and improve safety due to shock absorption capabilities. In addition, both of them help protect the axle or the shaft they are applied to from further wear while allowing smooth rotation or movement of parts within the machine.

Bushing vs Bearing

Bushing vs Bearing:Choose Wisely

When making a decision between bushings and bearings, it is important to consider several factors in order of importance:

- Velocity and Loading: Determine whether the wheels will carry heavier loads at slower speeds or lighter loads at higher speeds. Bearings are generally more suitable for high-velocity applications, while bushings tend to respond better to low-speed, heavy load scenarios.

- Smoothness of Operation: Consider the smoothness of operation, as bushings are more likely to experience "stick and slip" issues than bearings.

- Operating Noise: If minimal operating noise is critical, note that bushings are generally quieter than bearings.

- Maintenance and Lubrication: Take into account the maintenance and lubrication requirements, particularly in industries such as food and textiles where self-lubrication and low maintenance are favored.

- Budget: Finally, budget is a crucial factor, as bushings typically cost significantly less than bearings, making them a more cost-effective option.

Whether you're looking for bushings or bearings, understanding why each product exists and what benefits they have can help you make a good choice. If you need something that will last long term under heavier loads at higher speeds, then bearings are your best bet, but if you don't need anything too intense, then bushings should be sufficient enough. Generally speaking, bushings are more cost effective than bearings, so if you're on a tight budget they're a good option too! In a word, about the bearing and bushing selection, it really depends on your application needs.

Have questions about bearings and bushings? Send an Inquiry!

CATEGORIES

- Miniature Bearings(2)

- Thin Section Bearings(1)

- Ceramic Bearings(7)

- Stainless Steel Bearings(3)

- Needle Roller Bearings(3)

- Spherical Roller Bearings(1)

- Thrust Ball Bearings(2)

- Roller Bearings(1)

- Tapered Roller Bearings(2)

- Slewing Ring Bearings(2)

- Angular Contact Ball Bearings(1)

- Sleeve Bearings(1)

- Others(44)

- Low Temperature Bearings(1)

- Ball Bearings(9)

- Bearing Load(4)

- Bearing Components(1)

- Types of Bearings(4)

- Thrust Bearings(1)

- Bearing Technical Knowledge(19)

- Aerospace Bearings(2)

- Polyurethane Rollers(2)

- Cam Follower(3)

- Linear Bearings(1)

- Spherical Bearings(1)

LATEST ARTICLES

-

Chrome Steel vs. Stainless Steel Bearings: Which Do You Need?

Chrome Steel vs. Stainless Steel Bearings: Which Do You Need? -

Magnetic Bearings: What They Are & How They Work

Magnetic Bearings: What They Are & How They Work -

Expert Tips On Installing & Removing Bearings for Industry Professionals

Expert Tips On Installing & Removing Bearings for Industry Professionals -

How Much Grease to Put in Bearings: A Comprehensive Guide

How Much Grease to Put in Bearings: A Comprehensive Guide -

How to Clean Ceramic Bearings?

How to Clean Ceramic Bearings? -

Silicon Nitride Balls: Revolutionizing Precision Bearings

Silicon Nitride Balls: Revolutionizing Precision Bearings