Enhancing Optical Grade Mirrors with Super-Precision Angular Contact Ball Bearings

CONTENTS

- Customizing Solutions for High-Precision Applications

- The Superiority of Super-Precision Angular Contact Ball Bearings

- Enhanced Performance and Durability

- Advanced Bearing Features for Optical Grade Mirrors

- Ensuring Longevity in Harsh Environments

- Client Satisfaction and Customization Capabilities

- Lily Bearing's Expertise and Client Support

In the following case, Lily Bearing helped a client to customize a solution about super-precision angular contact ball bearings. This client is a main supplier of analytics for the food and agricultural industries worldwide. It can help optimize the use of food and agricultural resources by smart analytics. Among the client’s optical devices, the grade mirror is an ultra-precise instrument which can provide a new and intelligent way for food analysis.

Customizing Solutions for High-Precision Applications

Initially, the client used a kind of shaft only designed for deep groove ball bearings while designing the shafts of the optical grade mirrors. However, the precision of the deep groove ball bearings matched with the shafts of the grade mirror could not meet the requirement. In addition, the client was not convenient to change the design of the shafts again. In order to find more suitable bearings with higher precision on the basis of the original shaft design, the client made a comparison among many bearing suppliers and finally selected super-precision angular contact ball bearings from Lily Bearing.

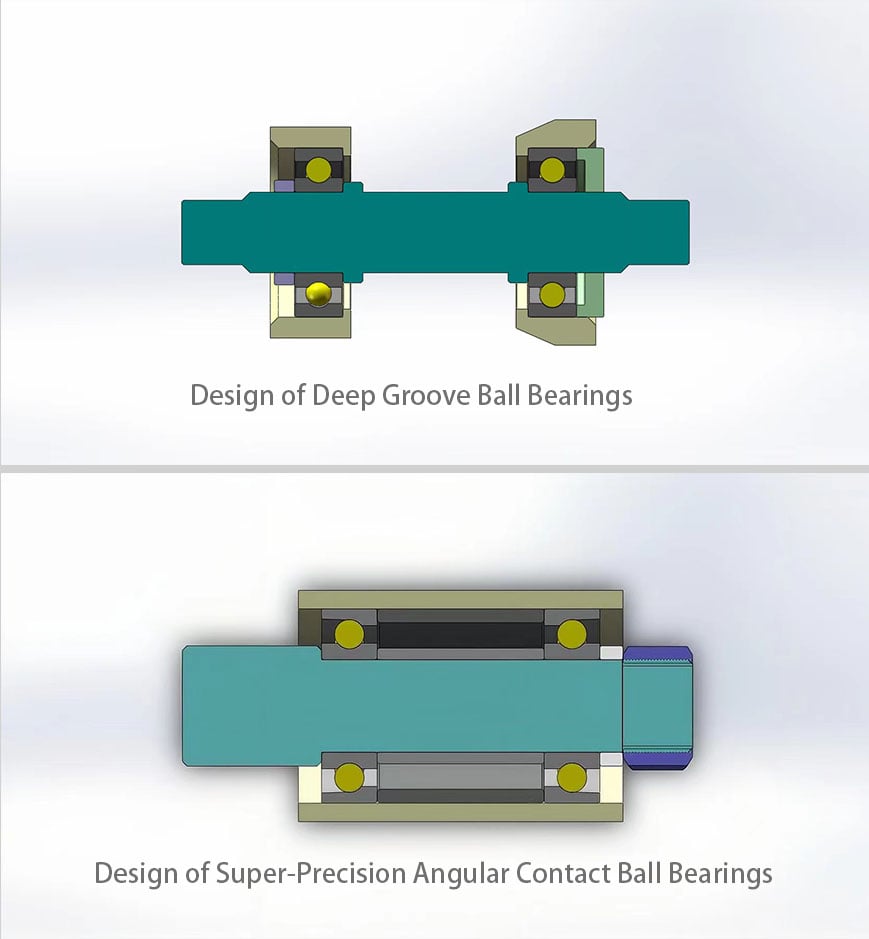

Comparison in design between deep groove ball bearings and super-precision angular contact ball bearings

The Superiority of Super-Precision Angular Contact Ball Bearings

Super-precision angular contact ball bearings are a class of bearings designed for applications requiring high precision, speed, and rigidity. Their superiority lies in several key aspects:

- High Precision and Accuracy: These bearings are manufactured to very tight tolerances, essential for applications where exact movements and minimal runout are crucial.

- Excellent High-Speed Capabilities: Designed to operate at very high speeds, these bearings are ideal for fast-rotating components, maintaining efficiency and performance under high-speed conditions.

- High Stiffness: Their construction offers a high degree of stiffness, resisting deformation under loads. This is vital for maintaining the precision of rotational movements in demanding applications.

- Support for Combined Loads: Thanks to their asymmetrical raceway design, they can effectively support both radial and axial loads, as well as combined loads, offering versatility across various applications.

- Low Heat Generation: Super-precision angular contact ball bearings are engineered to generate minimal heat, which is critical for maintaining bearing longevity and reliability, especially in high-speed applications.

Enhanced Performance and Durability

The selected angular contact ball bearings boast high stiffness and operate at extremely high speeds with minimal cross-sectional areas. This results in lower heat generation and extended bearing life. Notably, the bearings' angle significantly influences their axial load capacity, making them ideal for the precision required in optical grade mirrors.

Advanced Bearing Features for Optical Grade Mirrors

As far as the client's working conditions concerned, its optical grade mirror is an ultra-precision instrument, and thus the advanced equipment requires more excellent bearing performance.

According to the client's demands, Lily's engineers used the the sealed type of super precision angular contact ceramic ball bearings for the grade mirror. In the design, ceramic balls with high performance were arranged orderly in the bearings.

Thus, a grade mirror is fixed and then rotated with a limit of 100 degrees of rotation back and forth. The way of the bearing designing is proper because there are almost no loads. It can meet the client's needs of very low bearing vibration.

In order to ensure the high efficiency of the grade mirrors, experts recommended super-precision angular contact ball bearings with the grade P2, as P2 is the most precise grade.

High stiffness is also one of the main performance challenges in the specific application of grade mirrors. The reason is that the extent of elastic deformation determines the efficiency and accuracy of the optical grade mirrors under a certain load. Super-precision angular contact ball bearings are high stiffness bearings and thus make the grade mirrors operate well.

Lily’s super-precision angular contact ball bearings can bear heavy loads and provide high rigidity as well as high dynamic capability. They can also tackle challenges of high system stiffness with ease and meet the requirements of growing performance.

Sealed Super-Precision Angular Contact Ball Bearings with ceramic balls

Ensuring Longevity in Harsh Environments

Lily Bearing also considered the bearings' exposure to wet or corrosive environments. Using high-quality grease compliant with FDA regulations and NSF approved, the bearings were well-lubricated to ensure smooth operation. This grease is waterproof, anti-corrosive, and non-greasy, contributing to the bearings' stable performance. Additionally, seals were implemented to extend the grease life significantly.

Client Satisfaction and Customization Capabilities

The solution of super-precision angular contact ball bearings won good comments from this client in the end. In the email, the client mentioned, "...... Your super-precision angular contact ball bearings have many advantages ...... the low heat generation, the low noise and the low vibration level, what’s more, the high bearing capacity, the high reliability as well as the high precision ......"

It is true that the accuracy of super-precision angular contact ball bearings from Lily Bearing can be measured in the millimeter level. These bearings, which can accommodate shafts from 7 to 140 mm, are made according to two tolerance classes and two contact angles, following the requirements of both the speed and the stiffness.

Lily Bearing's Expertise and Client Support

With over 20 years of experience, Lily Bearing has established a reputation for supplying high-quality angular contact ball bearings. Their expertise extends to customizing bearings according to specific needs and conditions, providing top-notch services and support for selecting the right bearing models and troubleshooting any issues during usage.

Keep Learning