Cancel

System of Measurement

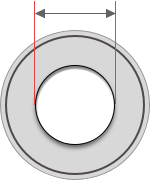

Bore Dia

Ring Material

For Load Direction

Outer Dia

Width

Seal Type

Cage Material

Ball Material

Dynamic

Static

Speed (x1k rpm)

Metric Size Standard Miniature Ball Bearings

400 Products Metric Size Standard Miniature Ball Bearings

They provide high precision, durability, and versatility in compact designs.

Metric Size Standard Miniature Ball Bearings

They provide high precision, durability, and versatility in compact designs.

Part Number

Ring

Material

Material

For Load

Direction

Direction

Bore Dia

Outer Dia

Width

Seal Type

Ball

Material

Material

Dynamic

Static

Speed

(x1k rpm)

(x1k rpm)

Price

68/0.6

Chrome Steel

Radial

0.6 mm

2.5 mm

1 mm

Open

Chrome Steel

13 lbf

3 lbf

128

$ 25.00

S68/0.6

440C Stainless Steel

Radial

0.6 mm

2.5 mm

1 mm

Open

440C Stainless Steel

12 lbf

3 lbf

128

$ 26.50

681

Chrome Steel

Radial

1 mm

3 mm

1 mm

Open

Chrome Steel

18 lbf

5 lbf

130

$ 15.00

S681

440C Stainless Steel

Radial

1 mm

3 mm

1 mm

Open

440C Stainless Steel

17 lbf

4 lbf

117

$ 18.00

691

Chrome Steel

Radial

1 mm

4 mm

1.6 mm

Open

Chrome Steel

27 lbf

7 lbf

100

$ 15.00

S691

440C Stainless Steel

Radial

1 mm

4 mm

1.6 mm

Open

440C Stainless Steel

24 lbf

6 lbf

90

$ 18.00

MR31

Chrome Steel

Radial

1 mm

3 mm

1.5 mm

Open

Chrome Steel

22 lbf

6 lbf

117

$ 16.00

SMR31

440C Stainless Steel

Radial

1 mm

3 mm

1.5 mm

Open

440C Stainless Steel

19 lbf

5 lbf

117

$ 19.00

SMR41x

440C Stainless Steel

Radial

1.2 mm

4 mm

1.8 mm

Open

440C Stainless Steel

23 lbf

7 lbf

130

$ 15.50

MR41x

Chrome Steel

Radial

1.2 mm

4 mm

1.8 mm

Open

Chrome Steel

25 lbf

7 lbf

105

$ 14.50

MR41xzz

Chrome Steel

Radial

1.2 mm

4 mm

2.5 mm

Shielded

Chrome Steel

25 lbf

7 lbf

105

$ 15.00

SMR41xzz

440C Stainless Steel

Radial

1.2 mm

4 mm

2.5 mm

Shielded

440C Stainless Steel

23 lbf

7 lbf

105

$ 16.50

601x

Chrome Steel

Radial

1.5 mm

6 mm

2.5 mm

Open

Chrome Steel

63 lbf

18 lbf

75

$ 12.50

S601x

440C Stainless Steel

Radial

1.5 mm

6 mm

2.5 mm

Open

440C Stainless Steel

57 lbf

16 lbf

67.5

$ 15.00

601xzz

Chrome Steel

Radial

1.5 mm

6 mm

3 mm

Shielded

Chrome Steel

63 lbf

18 lbf

75

$ 12.50

S601xzz

440C Stainless Steel

Radial

1.5 mm

6 mm

3 mm

Shielded

440C Stainless Steel

57 lbf

16 lbf

67.5

$ 15.00

681x

Chrome Steel

Radial

1.5 mm

4 mm

1.2 mm

Open

Chrome Steel

21 lbf

6 lbf

100

$ 12.50

S681x

440C Stainless Steel

Radial

1.5 mm

4 mm

1.2 mm

Open

440C Stainless Steel

19 lbf

5 lbf

90

$ 15.00

681xzz

Chrome Steel

Radial

1.5 mm

4 mm

2 mm

Shielded

Chrome Steel

21 lbf

6 lbf

100

$ 12.50

S681xzz

440C Stainless Steel

Radial

1.5 mm

4 mm

2 mm

Shielded

440C Stainless Steel

19 lbf

5 lbf

90

$ 15.00

691x

Chrome Steel

Radial

1.5 mm

5 mm

2 mm

Open

Chrome Steel

32 lbf

9 lbf

85

$ 12.50

S691x

440C Stainless Steel

Radial

1.5 mm

5 mm

2 mm

Open

440C Stainless Steel

29 lbf

8 lbf

76.5

$ 15.00

691xzz

Chrome Steel

Radial

1.5 mm

5 mm

2.6 mm

Shielded

Chrome Steel

32 lbf

9 lbf

85

$ 12.50

S691xzz

440C Stainless Steel

Radial

1.5 mm

5 mm

2.6 mm

Shielded

440C Stainless Steel

29 lbf

8 lbf

76.5

$ 15.00

602

Chrome Steel

Radial

2 mm

7 mm

2.8 mm

Open

Chrome Steel

74 lbf

23 lbf

60

$ 1.95

S602

440C Stainless Steel

Radial

2 mm

7 mm

2.8 mm

Open

440C Stainless Steel

66 lbf

21 lbf

54

$ 2.34

602 2rs

Chrome Steel

Radial

2 mm

7 mm

3.5 mm

Sealed

Chrome Steel

74 lbf

23 lbf

60

$ 1.95

S602 2rs

440C Stainless Steel

Radial

2 mm

7 mm

3.5 mm

Sealed

440C Stainless Steel

66 lbf

21 lbf

54

$ 2.34

602zz

Chrome Steel

Radial

2 mm

7 mm

3.5 mm

Shielded

Chrome Steel

74 lbf

23 lbf

60

$ 1.95

S602zz

440C Stainless Steel

Radial

2 mm

7 mm

3.5 mm

Shielded

440C Stainless Steel

66 lbf

21 lbf

54

$ 2.34

S672

440C Stainless Steel

Radial

2 mm

4 mm

1.2 mm

Open

440C Stainless Steel

25 lbf

8 lbf

98

$ 8.50

672

Chrome Steel

Radial

2 mm

4 mm

1.2 mm

Open

Chrome Steel

28 lbf

9 lbf

98

$ 7.50

S672zz

440C Stainless Steel

Radial

2 mm

4 mm

2 mm

Shielded

440C Stainless Steel

25 lbf

8 lbf

98

$ 8.95

672zz

Chrome Steel

Radial

2 mm

4 mm

2 mm

Shielded

Chrome Steel

28 lbf

9 lbf

98

$ 7.95

682

Chrome Steel

Radial

2 mm

5 mm

1.5 mm

Open

Chrome Steel

32 lbf

9 lbf

85

$ 1.95

S682

440C Stainless Steel

Radial

2 mm

5 mm

1.5 mm

Open

440C Stainless Steel

29 lbf

8 lbf

76.5

$ 2.34

682 2rs

Chrome Steel

Radial

2 mm

5 mm

2.3 mm

Sealed

Chrome Steel

32 lbf

9 lbf

85

$ 1.95

S682 2rs

440C Stainless Steel

Radial

2 mm

5 mm

2.3 mm

Sealed

440C Stainless Steel

29 lbf

8 lbf

76.5

$ 2.34

682zz

Chrome Steel

Radial

2 mm

5 mm

2.3 mm

Shielded

Chrome Steel

32 lbf

9 lbf

85

$ 1.95

S682zz

440C Stainless Steel

Radial

2 mm

5 mm

2.3 mm

Shielded

440C Stainless Steel

29 lbf

8 lbf

76.5

$ 2.34

692

Chrome Steel

Radial

2 mm

6 mm

2.3 mm

Open

Chrome Steel

63 lbf

18 lbf

75

$ 1.95

S692

440C Stainless Steel

Radial

2 mm

6 mm

2.3 mm

Open

440C Stainless Steel

57 lbf

16 lbf

67.5

$ 2.34

692 2rs

Chrome Steel

Radial

2 mm

6 mm

3 mm

Sealed

Chrome Steel

63 lbf

18 lbf

75

$ 1.95

S692 2rs

440C Stainless Steel

Radial

2 mm

6 mm

3 mm

Sealed

440C Stainless Steel

57 lbf

16 lbf

67.5

$ 2.34

692zz

Chrome Steel

Radial

2 mm

6 mm

3 mm

Shielded

Chrome Steel

63 lbf

18 lbf

75

$ 1.95

S692zz

440C Stainless Steel

Radial

2 mm

6 mm

3 mm

Shielded

440C Stainless Steel

57 lbf

16 lbf

67.5

$ 2.34

MR52

Chrome Steel

Radial

2 mm

5 mm

2 mm

Open

Chrome Steel

32 lbf

9 lbf

85

$ 1.95

SMR52

440C Stainless Steel

Radial

2 mm

5 mm

2 mm

Open

440C Stainless Steel

29 lbf

8 lbf

76.5

$ 2.34

MR52 2rs

Chrome Steel

Radial

2 mm

5 mm

2.5 mm

Sealed

Chrome Steel

32 lbf

9 lbf

85

$ 1.95

SMR52 2rs

440C Stainless Steel

Radial

2 mm

5 mm

2.5 mm

Sealed

440C Stainless Steel

29 lbf

8 lbf

76.5

$ 2.34

MR52zz

Chrome Steel

Radial

2 mm

5 mm

2.5 mm

Shielded

Chrome Steel

32 lbf

9 lbf

85

$ 1.95

SMR52zz

440C Stainless Steel

Radial

2 mm

5 mm

2.5 mm

Shielded

440C Stainless Steel

29 lbf

8 lbf

76.5

$ 2.34

MR62

Chrome Steel

Radial

2 mm

6 mm

2.5 mm

Open

Chrome Steel

63 lbf

18 lbf

75

$ 1.95

SMR62

440C Stainless Steel

Radial

2 mm

6 mm

2.5 mm

Open

440C Stainless Steel

57 lbf

16 lbf

67.5

$ 2.34

MR62 2rs

Chrome Steel

Radial

2 mm

6 mm

2.5 mm

Sealed

Chrome Steel

63 lbf

18 lbf

75

$ 1.95

SMR62 2rs

440C Stainless Steel

Radial

2 mm

6 mm

2.5 mm

Sealed

440C Stainless Steel

57 lbf

16 lbf

67.5

$ 2.34

MR62zz

Chrome Steel

Radial

2 mm

6 mm

2.5 mm

Shielded

Chrome Steel

63 lbf

18 lbf

75

$ 1.95

SMR62zz

440C Stainless Steel

Radial

2 mm

6 mm

2.5 mm

Shielded

440C Stainless Steel

57 lbf

16 lbf

67.5

$ 2.34

MR72

Chrome Steel

Radial

2 mm

7 mm

2.5 mm

Open

Chrome Steel

74 lbf

23 lbf

63

$ 1.95

SMR72

440C Stainless Steel

Radial

2 mm

7 mm

2.5 mm

Open

440C Stainless Steel

66 lbf

21 lbf

56.7

$ 2.34

MR72 2rs

Chrome Steel

Radial

2 mm

7 mm

3 mm

Sealed

Chrome Steel

74 lbf

23 lbf

63

$ 1.95

SMR72 2rs

440C Stainless Steel

Radial

2 mm

7 mm

3 mm

Sealed

440C Stainless Steel

66 lbf

21 lbf

56.7

$ 2.34

MR72zz

Chrome Steel

Radial

2 mm

7 mm

3 mm

Shielded

Chrome Steel

74 lbf

23 lbf

65

$ 1.95

SMR72zz

440C Stainless Steel

Radial

2 mm

7 mm

3 mm

Shielded

440C Stainless Steel

66 lbf

21 lbf

58.5

$ 2.34

602x

Chrome Steel

Radial

2.5 mm

8 mm

2.8 mm

Open

Chrome Steel

106 lbf

32 lbf

60

$ 1.75

S602x

440C Stainless Steel

Radial

2.5 mm

8 mm

2.8 mm

Open

440C Stainless Steel

95 lbf

29 lbf

54

$ 2.10

602x 2rs

Chrome Steel

Radial

2.5 mm

8 mm

4 mm

Sealed

Chrome Steel

106 lbf

32 lbf

60

$ 1.75

S602x 2rs

440C Stainless Steel

Radial

2.5 mm

8 mm

4 mm

Sealed

440C Stainless Steel

95 lbf

29 lbf

54

$ 2.10

602xzz

Chrome Steel

Radial

2.5 mm

8 mm

4 mm

Shielded

Chrome Steel

106 lbf

32 lbf

60

$ 1.75

S602xzz

440C Stainless Steel

Radial

2.5 mm

8 mm

4 mm

Shielded

440C Stainless Steel

95 lbf

29 lbf

54

$ 2.10

682x

Chrome Steel

Radial

2.5 mm

6 mm

1.8 mm

Open

Chrome Steel

40 lbf

13 lbf

71

$ 1.75

S682x

440C Stainless Steel

Radial

2.5 mm

6 mm

1.8 mm

Open

440C Stainless Steel

36 lbf

12 lbf

63.9

$ 2.10

682x 2rs

Chrome Steel

Radial

2.5 mm

6 mm

2.6 mm

Sealed

Chrome Steel

40 lbf

13 lbf

71

$ 1.75

S682x 2rs

440C Stainless Steel

Radial

2.5 mm

6 mm

2.6 mm

Sealed

440C Stainless Steel

36 lbf

12 lbf

63.9

$ 2.10

682xzz

Chrome Steel

Radial

2.5 mm

6 mm

2.6 mm

Shielded

Chrome Steel

40 lbf

13 lbf

71

$ 1.75

S682xzz

440C Stainless Steel

Radial

2.5 mm

6 mm

2.6 mm

Shielded

440C Stainless Steel

36 lbf

12 lbf

63.9

$ 2.10

692x

Chrome Steel

Radial

2.5 mm

7 mm

2.5 mm

Open

Chrome Steel

74 lbf

23 lbf

63

$ 1.75

S692x

440C Stainless Steel

Radial

2.5 mm

7 mm

2.5 mm

Open

440C Stainless Steel

66 lbf

21 lbf

56.7

$ 2.10

692x 2rs

Chrome Steel

Radial

2.5 mm

7 mm

3.5 mm

Sealed

Chrome Steel

74 lbf

23 lbf

63

$ 1.75

S692x 2rs

440C Stainless Steel

Radial

2.5 mm

7 mm

3.5 mm

Sealed

440C Stainless Steel

66 lbf

21 lbf

56.7

$ 2.10

692xzz

Chrome Steel

Radial

2.5 mm

7 mm

3.5 mm

Shielded

Chrome Steel

74 lbf

23 lbf

63

$ 1.75

S692xzz

440C Stainless Steel

Radial

2.5 mm

7 mm

3.5 mm

Shielded

440C Stainless Steel

66 lbf

21 lbf

56.7

$ 2.10

MR82x

Chrome Steel

Radial

2.5 mm

8 mm

2.5 mm

Open

Chrome Steel

107 lbf

32 lbf

60

$ 1.75

SMR82x

440C Stainless Steel

Radial

2.5 mm

8 mm

2.5 mm

Open

440C Stainless Steel

96 lbf

29 lbf

54

$ 2.10

MR82x 2rs

Chrome Steel

Radial

2.5 mm

8 mm

2.5 mm

Sealed

Chrome Steel

107 lbf

32 lbf

60

$ 1.75

SMR82x 2rs

440C Stainless Steel

Radial

2.5 mm

8 mm

2.5 mm

Sealed

440C Stainless Steel

96 lbf

29 lbf

54

$ 2.10

MR82xzz

Chrome Steel

Radial

2.5 mm

8 mm

2.5 mm

Shielded

Chrome Steel

107 lbf

32 lbf

60

$ 1.75

SMR82xzz

440C Stainless Steel

Radial

2.5 mm

8 mm

2.5 mm

Shielded

440C Stainless Steel

96 lbf

29 lbf

54

$ 2.10

S603

440C Stainless Steel

Radial

3 mm

9 mm

3 mm

Open

440C Stainless Steel

47 lbf

31 lbf

50.4

$ 1.38

603

Chrome Steel

Radial

3 mm

9 mm

3 mm

Open

Chrome Steel

52 lbf

34 lbf

56

$ 1.15

S603 2rs

440C Stainless Steel

Radial

3 mm

9 mm

5 mm

Sealed

440C Stainless Steel

47 lbf

31 lbf

50.4

$ 1.38

603 2rs

Chrome Steel

Radial

3 mm

9 mm

5 mm

Sealed

Chrome Steel

52 lbf

34 lbf

56

$ 1.15

603zz

Chrome Steel

Radial

3 mm

9 mm

5 mm

Shielded

Chrome Steel

52 lbf

34 lbf

56

$ 1.15

S603zz

440C Stainless Steel

Radial

3 mm

9 mm

5 mm

Shielded

440C Stainless Steel

47 lbf

31 lbf

50.4

$ 1.38

623

Chrome Steel

Radial

3 mm

10 mm

4 mm

Open

Chrome Steel

121 lbf

39 lbf

50

$ 1.15

S623

440C Stainless Steel

Radial

3 mm

10 mm

4 mm

Open

440C Stainless Steel

108 lbf

36 lbf

45

$ 1.38

S623 2rs

440C Stainless Steel

Radial

3 mm

10 mm

4 mm

Sealed

440C Stainless Steel

108 lbf

36 lbf

45

$ 1.38

623 2rs

Chrome Steel

Radial

3 mm

10 mm

4 mm

Sealed

Chrome Steel

121 lbf

39 lbf

50

$ 1.15

S623zz

440C Stainless Steel

Radial

3 mm

10 mm

4 mm

Shielded

440C Stainless Steel

108 lbf

36 lbf

45

$ 1.38

623zz

Chrome Steel

Radial

3 mm

10 mm

4 mm

Shielded

Chrome Steel

121 lbf

39 lbf

50

$ 1.15