Flow Meter Miniature Bearings

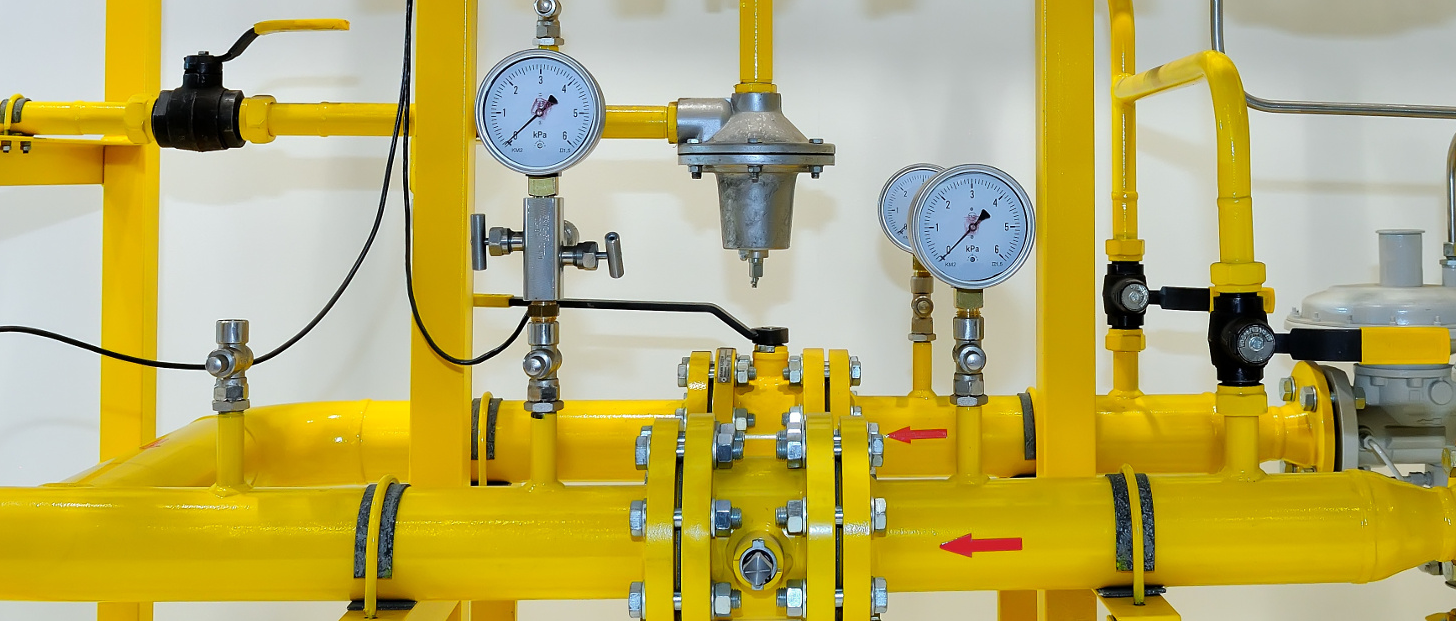

Flow meter miniature precision bearings are designed to meet the strict requirements of various flow meters. Such micro bearings can be used not only in turbine flow meters which project the flow rate by calculating the rotational speed, but also in Differential pressure flow meters as well as in Waist wheel flow meters which work by means of the rotation of the internal metering chamber. Flow meter miniature bearings have a high precision. They can provide accurate measure of linear, nonlinear or volumetric flow rate of a liquid or a certain gas.They can even be found applications in some harsh applications such as oil and gas pipelines or corrosive chemical processing industries, etc.

The engineer team from Lily Bearing have rich experience in flow meter bearing applications. Factors, such as the materials, the maintenance demands, the pollutants as well as the flow components, are always taken into account in the design of flow meter miniature bearings. They can help specify the right bearings for detailed applications.

-

●Materials with high corrosion resistance:The flow meter mini bearings are made from materials with high corrosion resistance, such as high nitrogen steel (X30CrMoN15-1) or 440C stainless steel and so on, to meet the technical needs of the flow meters.

-

●Low running friction & low adhesive wear:The stainless steel bearings used in flow meters provide high strength, low friction and low adhesive wear at any point in the bearing's life cycle and thus ensure high performance.

-

●Low Torque:With special techniques, Lily Bearing has developed new kinds of miniature bearings which can stand up to the extremely low torque needs of flow meters and can enable flow meters to measure the smallest flow rates in an easy way. Flow meter miniature bearings are sure to bring good performance to manufacturers who try to seek the lowest start-up torque and the low flow measurements.

-

●Sealing:To avoid contaminants, flow meter miniature bearings offer a range of sealing options, including shielded sealing, etc.

-

●Suitability for operation in high temperature and high speed environment:Conventionally, the temperatures Lily’s flow meter miniature bearings can withstand is in the range of -30° to 110°. Some of them can also withstand a temperature range of -86°F to 230°F.

-

●High Precision:The flow meter miniature bearings are equipped with high running precision. They can ensure accurate measurement of different fluids in certain applications.

-

●Minimized maintenance cost & long life:The aim of Lily Bearing has always been to help clients keep the maintenance costs to a minimum and achieve a long bearing life.

-

●Customized designs:In some harsh applications, the engineering team will also help customize the flow meter miniature bearings according to the clients' working conditions as well as their special needs. The materials are not only limited to those which are mentioned above, but also different kinds of ceramics included. The setting of technical parameters will also be combined with the specific working conditions. In a word, configurations of flow meter miniature bearings can always be tailored to comply with each application, including the variations of materials for the raceways, cages, balls, special lubrication as well as coating elements and so on.

-

●Model interchange with international famous brands:Lily’s flow meter miniature bearings are equipped with stable performance and high precision design. They are a great alternative to major international brands (such as EZO, Myonic, GRW, etc.). In Lily’s website, it is easy to achieve model interchangeability.

-

●Chemical processing systems of corrosive liquid or gas

-

●Oil or gas pipeline measurement

-

●Utility monitoring

-

●Energy production industry

-

●HVAC systems

-

●Food and beverage field