Low Temperature Bearings: Benefits, Applications & Selection

Low temperature bearings, also known as cryogenic bearings, are designed to operate in extreme low temperature environments ranging from minus 40 degrees Celsius to minus 120 degrees Celsius. These specialized bearings are crucial for various applications in industries such as aerospace, deep sea exploration, and liquid nitrogen equipment.

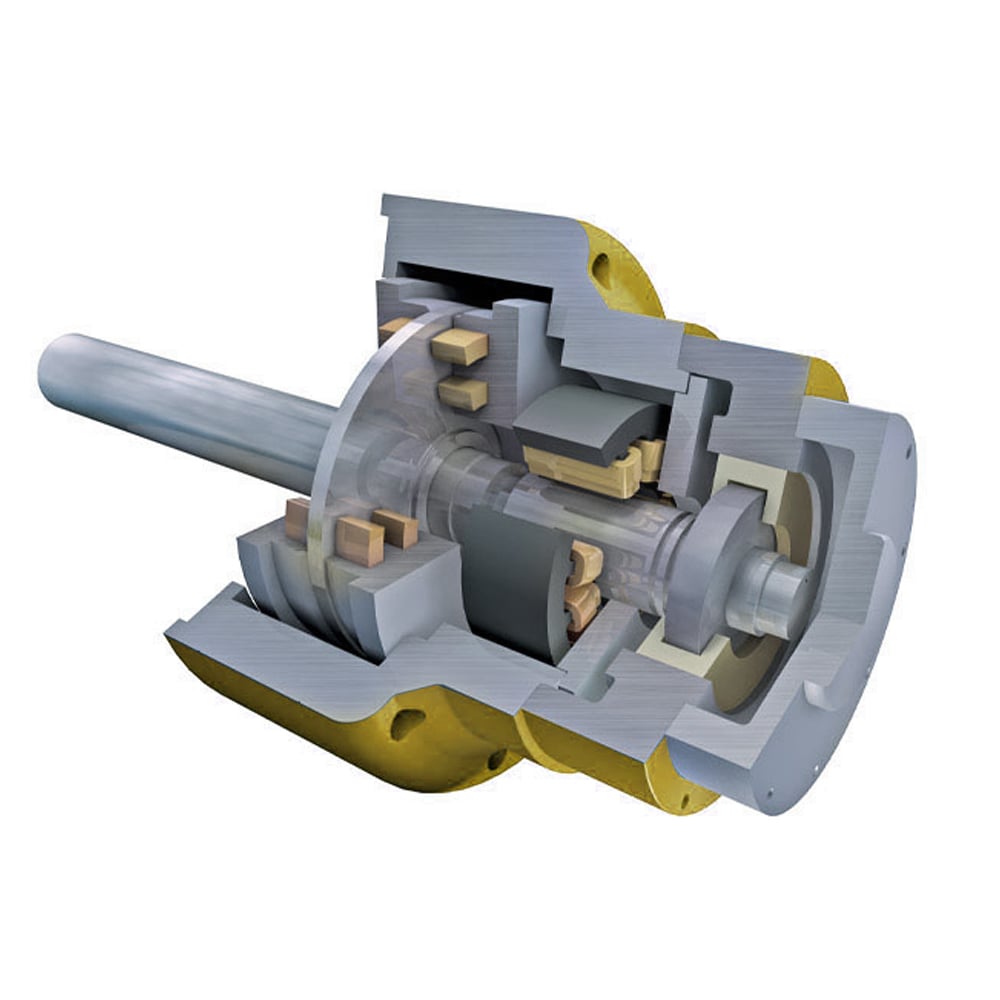

Low Temperature Bearings

Materials of Low Temperature Bearings

Low temperature bearings are available in various materials including 52100 Chrome Steel, stainless steel, and ceramics. The current 52100 Chrome Steel and stainless steel bearings can reach temperatures as low as minus 60 degrees Celsius. However, ultra-low temperature ceramic bearings can withstand temperatures as low as minus 90 degrees Celsius to minus 120 degrees Celsius. These ultra-low temperature bearings are patented and have special ultra-low temperature grease production, which has high viscosity and a low pour point that can be applied to different low temperature conditions.

Low Temperature Bearing - stainless steel bearing

Advantages of Low Temperature Bearings

Low temperature bearings are designed to withstand extremely low temperatures, which ordinary bearings cannot. Ordinary bearings can only withstand temperatures as low as minus 40 degrees Celsius, and at such low temperatures, the internal crystallization affects the rotation, which results in the bearing being directly frozen and locked. In contrast, low temperature bearings are engineered to avoid this issue, ensuring reliable and consistent performance in low temperature environments.

Applications of Low Temperature Bearings

Low temperature bearings are commonly used in various industries, including aerospace, deep sea exploration, and liquid nitrogen equipment. In aerospace applications, low temperature bearings are critical for the safe operation of aircraft in extreme temperatures. In deep sea exploration, cryogenic bearings are essential to maintain the performance of underwater vehicles in sub-zero temperature environments. Finally, in liquid nitrogen equipment, low temperature bearings are used to prevent damage caused by temperature changes and ensure the equipment operates efficiently.

How to Choose Low Temperature Bearings

When selecting low temperature bearings, several factors should be considered to ensure that the bearings meet the specific application requirements.

-

Operating Temperature

The operating temperature is the most crucial factor to consider when selecting low temperature bearings. It is important to know the minimum and maximum operating temperatures of the application. Low temperature bearings are designed to operate in extremely low temperatures, which ordinary bearings cannot withstand. However, different types of low temperature bearings have different temperature ranges.

For instance, 52100 Chrome Steel and stainless steel bearings can reach temperatures as low as minus 60 degrees Celsius, while ultra-low temperature ceramic bearings can withstand temperatures as low as minus 90 degrees Celsius to minus 120 degrees Celsius. It is essential to choose a bearing that can withstand the temperature range of the application to ensure reliable and consistent performance.

-

Load Capacity

The load capacity is another important factor to consider when selecting low temperature bearings. The load capacity refers to the amount of weight the bearing can support under a specific set of conditions. It is important to choose a bearing that can handle the load capacity of the application. If the load capacity exceeds the maximum limit of the bearing, it can result in premature wear and failure of the bearing.

Low Temperature Bearing - ceramic bearing

-

Lubrication

Lubrication is crucial for the proper functioning of bearings. It is important to choose a bearing with the right type of lubricant that can withstand the low-temperature environment. The lubricant must have a low pour point and high viscosity to ensure that it does not freeze or become too thick in the low-temperature environment. Some low temperature bearings come pre-greased with special ultra-low temperature grease production, which has high viscosity and a low pour point that can be applied to different low-temperature conditions. It is important to select the right lubricant for the bearing to ensure that it operates efficiently and has a longer lifespan.

-

Material Compatibility

The material compatibility is another important factor to consider when selecting low temperature bearings. The bearing material should be compatible with the other materials in the application to ensure reliable and consistent performance. Different types of low temperature bearings are available in various materials, including 52100 Chrome Steel, stainless steel, and ceramics. Each material has its unique properties that make it suitable for specific applications. It is essential to choose a bearing material that is compatible with the other materials in the application to avoid any compatibility issues.

Conclusion

Low temperature bearings are a specialized type of bearing that can operate in extreme low temperature environments ranging from minus 40 degrees Celsius to minus 120 degrees Celsius. These bearings are available in different materials and have several advantages over ordinary bearings. They are crucial for various applications in industries such as aerospace, deep sea exploration, and liquid nitrogen equipment. If you require low temperature bearings for your application, it is important to understand the unique characteristics of these bearings and to work with a trusted supplier to ensure that the bearings meet your requirements.

CATEGORIES

- Miniature Bearings(2)

- Thin Section Bearings(1)

- Ceramic Bearings(7)

- Stainless Steel Bearings(3)

- Needle Roller Bearings(3)

- Spherical Roller Bearings(1)

- Thrust Ball Bearings(2)

- Roller Bearings(1)

- Tapered Roller Bearings(2)

- Slewing Ring Bearings(2)

- Angular Contact Ball Bearings(1)

- Sleeve Bearings(1)

- Others(44)

- Low Temperature Bearings(1)

- Ball Bearings(9)

- Bearing Load(4)

- Bearing Components(1)

- Types of Bearings(4)

- Thrust Bearings(1)

- Bearing Technical Knowledge(20)

- Aerospace Bearings(2)

- Polyurethane Rollers(2)

- Cam Follower(3)

- Linear Bearings(1)

- Spherical Bearings(1)

LATEST ARTICLES

-

The Impact of Counterfeit Bearings On the Industry and How to Avoid Them

The Impact of Counterfeit Bearings On the Industry and How to Avoid Them -

Chrome Steel vs. Stainless Steel Bearings: Which Do You Need?

Chrome Steel vs. Stainless Steel Bearings: Which Do You Need? -

Magnetic Bearings: What They Are & How They Work

Magnetic Bearings: What They Are & How They Work -

Expert Tips On Installing & Removing Bearings for Industry Professionals

Expert Tips On Installing & Removing Bearings for Industry Professionals -

How Much Grease to Put in Bearings: A Comprehensive Guide

How Much Grease to Put in Bearings: A Comprehensive Guide -

How to Clean Ceramic Bearings?

How to Clean Ceramic Bearings?