Cancel

Ball Bearing Design And Working Principle Introduction

By Bearing Manufacturer>Bearing News>Ball bearing design and working principle introduction

?2004-2012

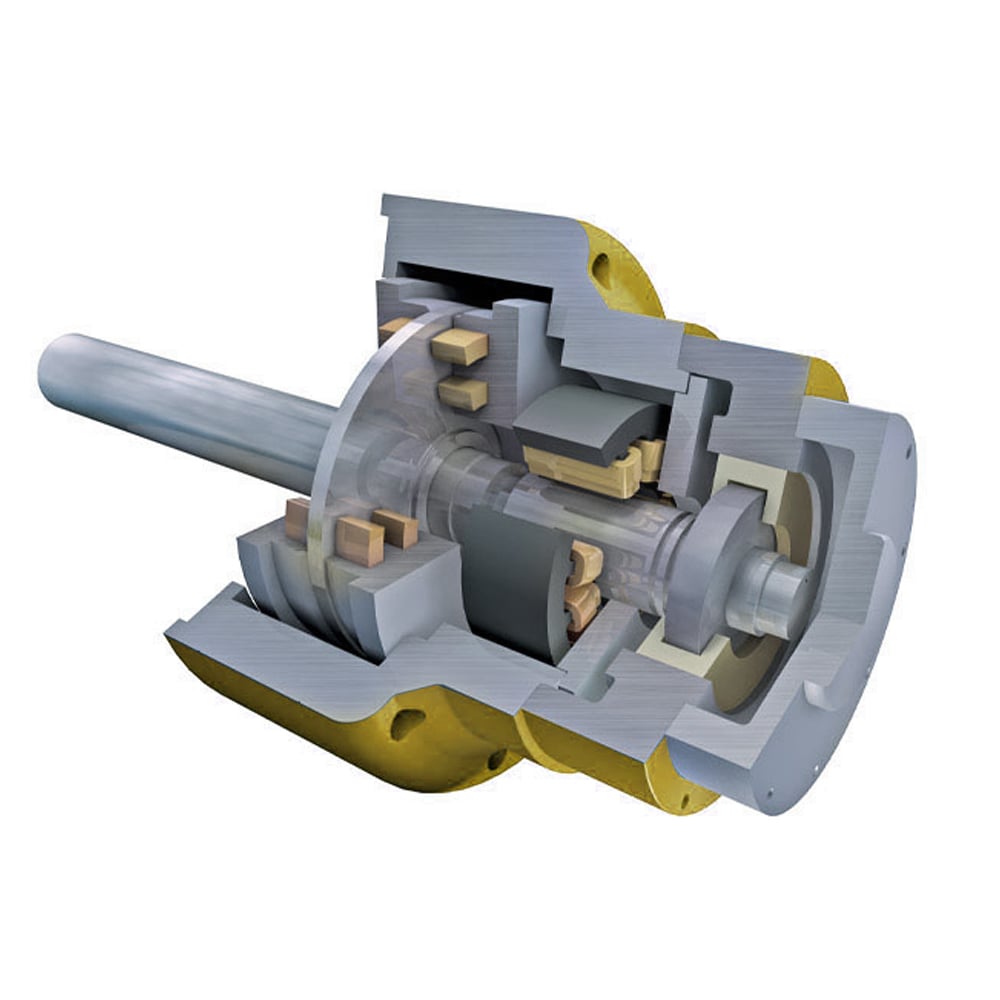

Ball bearings are the most common types. Basic ball bearing design is by the outer, inner ring, ball and cage composition. Ball bearing is the most representative of the rolling bearing, wide range of USES. Suitable for high speed operation, and very durable, often without maintenance.

Ball bearing design can bear larger load, because the ball loading, the steel and the middle of the steel, so it is also called the ball bearing. Ball and the internal and external ring is usually made chrome steel, hardness is about 61-65 between, and maintainer of the lower hardness. Its material has a metal or nonmetal. Ball bearing design than journal bearing friction resistance is small, so the same speed, lower temperature.

Ball bearing friction coefficient is small, the limit speed is high, simple structure, low manufacture cost. So widely used in precision instrument, low noise machine, automobile, motorcycle and general machinery and other industries, is the most widely used in mechanical industry of bearing. According to the different USES and materials, let us simple introduced as follows the ball bearing.

Deep Groove Ball Bearings mainly bear radial load, also can also bear radial load and axial load. Its structure is simple, and other types of easy to achieve higher than the manufacturing accuracy, and therefore easy to into a series of mass production, manufacturing cost is low, the use of very common. Deep Groove Ball Bearings have single row and double rows two. It can be used for transmission, instruments and meters, electric motor, electric appliance, internal combustion engine, transportation vehicles, agricultural machinery, construction machinery, engineering machinery, such as the yo-yo

Needle Roller Bearings basic structure and NU type cylindrical Roller bearing the same, but because the Needle, the volume can be reduced, and can withstand large radial load without inner ring of bearing the has an appropriate precision and hardness of the shaft installation surface as raceway surface use. The main applicable cage: steel plate stamping cage. Its main use: automobile engine, transmission, pump, excavator crawler wheel, hoist, bridge crane, compressor.

Along with the car forward high speed, high reliability, low energy consumption direction of development, Water Pump Bearings also requires light weight, small volume, big flow, high speed. Water Pump Bearings is a sort of large carrying capacity, good rigidity, rotary accuracy is high, the service life is long, rational structure, reliable work of new bearing. At present, not only widely used in automotive cooling water pump, in textile machinery, engineering machinery and other aspects have been widely used.

CATEGORIES

- Miniature Bearings(2)

- Thin Section Bearings(1)

- Ceramic Bearings(7)

- Stainless Steel Bearings(3)

- Needle Roller Bearings(3)

- Spherical Roller Bearings(1)

- Thrust Ball Bearings(2)

- Roller Bearings(1)

- Tapered Roller Bearings(2)

- Slewing Ring Bearings(2)

- Angular Contact Ball Bearings(1)

- Sleeve Bearings(1)

- Others(44)

- Low Temperature Bearings(1)

- Ball Bearings(9)

- Bearing Load(4)

- Bearing Components(1)

- Types of Bearings(4)

- Thrust Bearings(1)

- Bearing Technical Knowledge(20)

- Aerospace Bearings(2)

- Polyurethane Rollers(2)

- Cam Follower(3)

- Linear Bearings(1)

- Spherical Bearings(1)

LATEST ARTICLES

-

The Impact of Counterfeit Bearings On the Industry and How to Avoid Them

The Impact of Counterfeit Bearings On the Industry and How to Avoid Them -

Chrome Steel vs. Stainless Steel Bearings: Which Do You Need?

Chrome Steel vs. Stainless Steel Bearings: Which Do You Need? -

Magnetic Bearings: What They Are & How They Work

Magnetic Bearings: What They Are & How They Work -

Expert Tips On Installing & Removing Bearings for Industry Professionals

Expert Tips On Installing & Removing Bearings for Industry Professionals -

How Much Grease to Put in Bearings: A Comprehensive Guide

How Much Grease to Put in Bearings: A Comprehensive Guide -

How to Clean Ceramic Bearings?

How to Clean Ceramic Bearings?